Stack Testing

Ankersmid Sampling

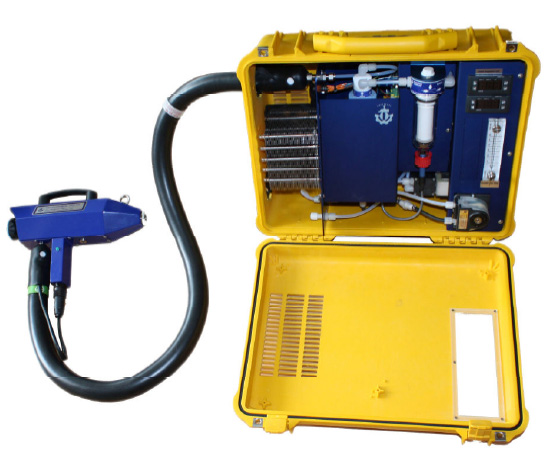

APS Portable Gas Sampling System

The emission of pollutants resulting from a multitude of activities (industry, transport, …) alters the atmospheric composition and degrade air quality. Control of gaseous pollutant emissions in the atmosphere has become a major challenge for the protection of human health and the environment. To avoid these risks, the regulation has established discharge limits thresholds for certain pollutants and requires periodic inspections whose frequency depends on the type of activity (from 3 months to 3 years). Accredited stack testing companies are responsible for conducting short to medium term environmental compliance monitoring tasks in a wide range of industries and processes such as power plants and large manufacturing facilities including paper mill, foundry, waste recycling facilities, refineries…

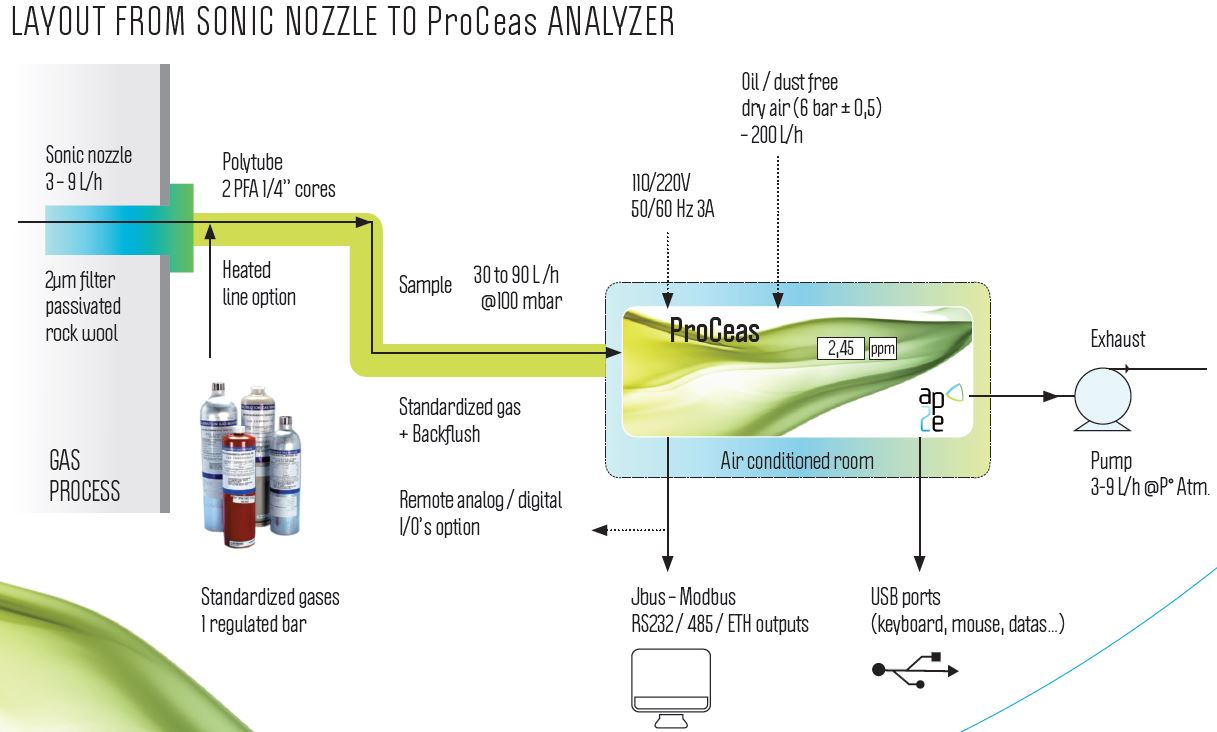

Prior to be analysed, the gas extracted from the discharge stack or process duct requires delicate conditioning which mainly consist of particulate filtration and moisture removal. Failure to achieve an efficient sample preparation can results in inaccurate measurements, loss of data or damaged equipment.

While stack testers and local authorities are continuously devoting time and knowledge to optimise the methods and protocols related to short to medium terms mandatory analysis campaign, ANKERSMID® has invested its long time expertise in developing the APS Portable Gas Conditioning Systems in direct collaboration with leading stack testing companies.

As a result, ANKERSMID® Portable Sampling System APS provides stack testers with features tailored to short term source testing in a robust and light weight design. The complete systems responds to today’s demand in terms of operation and compliance.

ANKERSMID®

Portable Sampling System APS

ANKERSMID® Portable Sampling System APS is a complete gas sampling train composed of:

The APP Heated Gas Sampling Probe is a light weight sampling gun enabling high temperature filtration directly at the sampling point.

The probe is heated up to 180°C in order to maintain the sample temperature above acid gases dew point. A filter element of 150 mm is integrated, suitable for most applications up to 1g of dust per cubic meter of emissions. Thanks to its design, the filter can be replaced or checked without the need of dismounting the probe. For applications where the dust load reaches 10 g/m³, a blow-back option can be fitted. Calibration gas can be injected directly into the probe through the calibration gas port according to emission monitoring standards enforcing test gas feeding via the probe’s filter element.

180°C operating temperature

Integrated over temperature safety switch

Low temperature alarm contact

Test gas port according to EN14181 available as standard

Light weight

Ready to operate in 15 minutes

Low and Easy maintenance

Universal mounting clamp for heated line

Compact design and universal applicability, easy handling with mounting eye on housing (2m chain incl.)

APP150 Portable heavy duty ABS case for safe transport

The AHL Heated sample line is perfectly suited to mobile applications. It features a highly flexible smooth silicon outer jacket and can be fitted with options enabling efficient installation and operation:

- Quick connect fittings at both ends: stainless steel pressure release connector directly inserted into the heated lines hard cap terminations (no cold spot)

- Built-in cable with plugs to feed the APP sampling probe with power – No additional cable or power source required at the sampling location.

- Additional inner tubes for test gas (calibration via probe filter) or compressed air (back-flush)

The APS portable sampling system is designed so that detailed gas analysis can be carried out at any time in any place. The entire sampling system is housed in a compact and robust carrying case which ensures safe transport and easy set-up. All the components can be easily accessed for inspection or routine maintenance. The APS concept allows you to perform gas analysis in an efficient manner, safely and with a minimum of maintenance. This system ensures reliable sample preparation without loss and prevents damage on the downstream analysis system. It is suitable for a large range of applications and has already been adopted by many stack testers around the world.

Fully automated

Moisture alarm (detection of sample condensates)

Extremely stable dew point +/-1 degree C

Optimal reliability

Compact and robust design

Light weight

Ready to operate in 15 minutes

Low and Easy maintenance

PFA coated heat exchanger

PTFE coated sampling pump

Preliminary sample filter

Built-in temperature controller for the heated line

AquaGas Pty Ltd

Integrated high performance monitoring solutions

AquaGas Pty Ltd has the tools and technologies needed to accurately measure atmospheric emissions of gaseous pollutants helping you in improving air quality and environmental performances.

ANKERSMID® , well-known in the monitoring industry as Ankersmid M&C, has the benefits of 30 years of experience in developing state of the art gas sampling and gas conditioning equipment tailored to CEMS (Continuous Emissions Monitoring Systems) and stack testing (short to medium term measurements). Subsidiaries in several countries (Netherlands, France, China, Roumania, Germany, Korea…) and more than 100 employees world-wide place ANKERSMID® in a leading position within the field of environmental monitoring and process control instrumentation.