NOx Emissions Testing

The emission of pollutants resulting from a multitude of activities (industry, transport, …) alters the atmospheric composition and degrade air quality. Control of gaseous pollutant emissions in the atmosphere has become a major challenge for the protection of human health and the environment. To avoid these risks, the regulation has established discharge limits thresholds for certain pollutants and requires periodic inspections whose frequency depends on the type of activity (from 3 months to 3 years). Accredited stack testing companies and/or Site Environmental Managers are responsible for conducting short to medium term environmental compliance monitoring tasks in a wide range of industries and processes such as power plants and large manufacturing facilities including paper mill, foundry, waste recycling facilities, refineries…

NOx Portable Analysers

for Environmental Compliance in the power generation industry

Our customer, manufacturers and distributor of diesel, gas engines and power systems, has chosen AquaGas Monitoring Systems for the supply of handheld and portable NOx gas analysers. Convinced by the achieved performances, our client is using nowaday the GA12Plus and GA40TPlus gas analysers to ensure environmental compliance, combustion efficiency and optimal operating conditions of their small to large scale onsite power generators and associated filtration systems.

Each analyser comes with built in logger, NO, NO2 and O2 gas proprietary measuring cells, stack temperature sensor, flow and velocity measurement, advanced sampling systems, programmable monitoring sequences, wireless communications and deliver real time normalised (O2, Pressure and Temperature compensated, corrected on dry gas) concentrations with up to 18 hrs battery life.

The GA12 and GA40TPlus are multigas analysers and monitoring concept develop by Madur electronics. Madur was initially founded in 1984 in Vienna Austria and is now worldwide recognised manufacturer of reliable and cost effective equipment for gas analysis applications. Since 2013, Madur operates sales, production, service and R&D from their headquarters located in Poland to provide customers the most advanced solutions, the fastest possible with professional services and ongoing technical support.

MADE TO MEASURE

Environmental Monitoring and Process Control

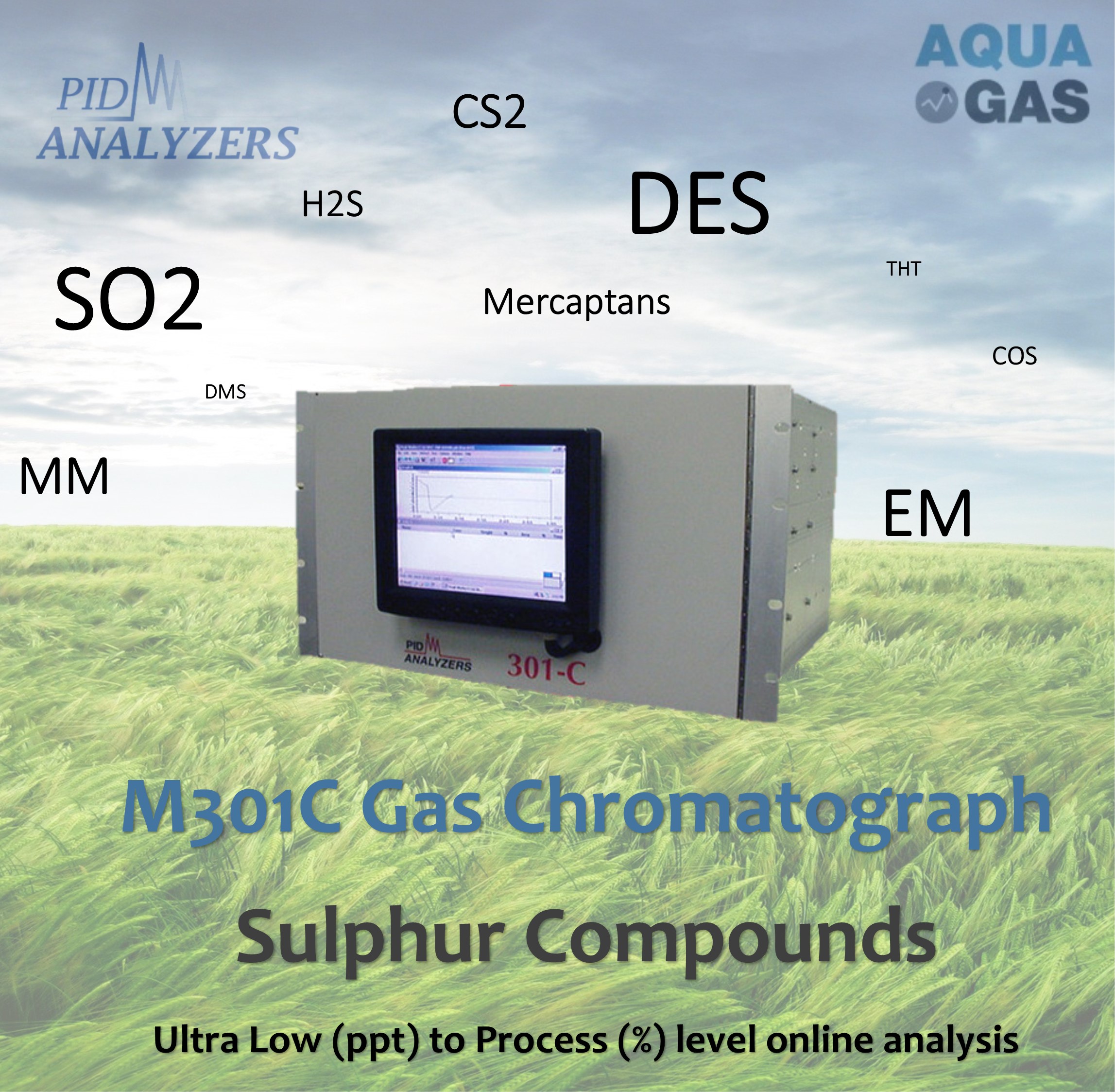

AquaGas is supporting the global industrial community with high performance environmental and process monitoring systems (Continuous Emissions Monitoring Systems, Air Quality Monitoring Systems, Online process analysers, Water Quality Monitoring Systems) specifically designed and built to meet your application requirements.