WT1 Fence Line Monitoring Solution

/in 3 to 17 µm), Air Quality, Applications, ASTM E679), environmental impact assessment and air quality control applications in urban and industrial areas, EU ( 2008 /50/EC), fenceline monitoring system, gas detection, IAQ, Indoor air quality, New products, New project, OH&S, oor air quality, Ozone, safety at work, USEPA ( 40 CFR Part 53), workstation solutions /by aymericFenceline Monitoring Solution for realtime mapping of physicals, chemicals and biologicals air pollutions.

“MADE TO MEASURE” for the growing demand for flexible and affordable air pollution monitoring solutions, the WT1 is a multiparameter Fence Line Monitoring System easily deployable for smart cities mapping, roadside monitoring, air pollution and odours control at industrial sites, remediation sites as well as background air studies and environmental impact assessment. The WT1 Fence Line Monitoring System is designed by Ellona Senses & Instrumentation for realtime measurement of air quality, noise, odours and vibrations in urban and rural area.

Autonomous & Wireless, WT1® Watchtower fenceline monitoring system is designed for air pollution monitoring, environmental impact assessment and air quality control applications in urban and industrial areas. WT1® fenceline monitoring system consists in a network of field-based Gas & Odours monitoring stations with high precision sensors for low ppb gas concentrations in ambient air (H2S, RSH, NO2, NH3, SO2 …) in addition to VOC, odours, noise and particulates (from 0,3 to 17 µm). With its cutting edge cloud based data processing system (Rubix Soft SAS), the WT1® provides secured access from PC, Tablets or Phone to realtime reading, average, trends and mapping of gas concentration with alarms and instrument status. The WT1® also offers key functions for odours surveys, plume prediction and air pollution impact assessment such as the ability to correlate high accuracy measurements in ppm, ppb or OU/M3 with sensory perception from multiple users (inspectors, surveyors or operators) and locations.

WT1® fenceline monitoring system complies with

• Odour unit (EN 13725, ASTM E679)

• USEPA ( 40 CFR Part 53)

• EU ( 2008 /50/EC)

Scalable monitoring solution

Modular and scalable, the WT1® fenceline monitoring system network is sized to your needs. Clear and accurate environmental data from Standalone analyser or sensors network are available source by source, site by site or on a regional scale. Scalable instrument network for cities, large remediation sites, industrial areas, the WT1® fenceline monitoring system provides real-time air pollution data for efficient management of chemicals and olfactory pollution.

Realtime impact assessment

Real Time alarm, customised mapping with online air pollution and nuisances data available from the Ellona Software Platform secured website, using any web browser to access safely your data, 24/7, anywhere in the world, the WT1 is a versatile tool for impact assessment and air pollution control in and around construction sites, industrial facilities.

Increased air pollution control capabilities

Correlation with reference instruments can be provided via automatic on line sampling and dynamic olfactometry or field olfactometry and a simple correlation model building.

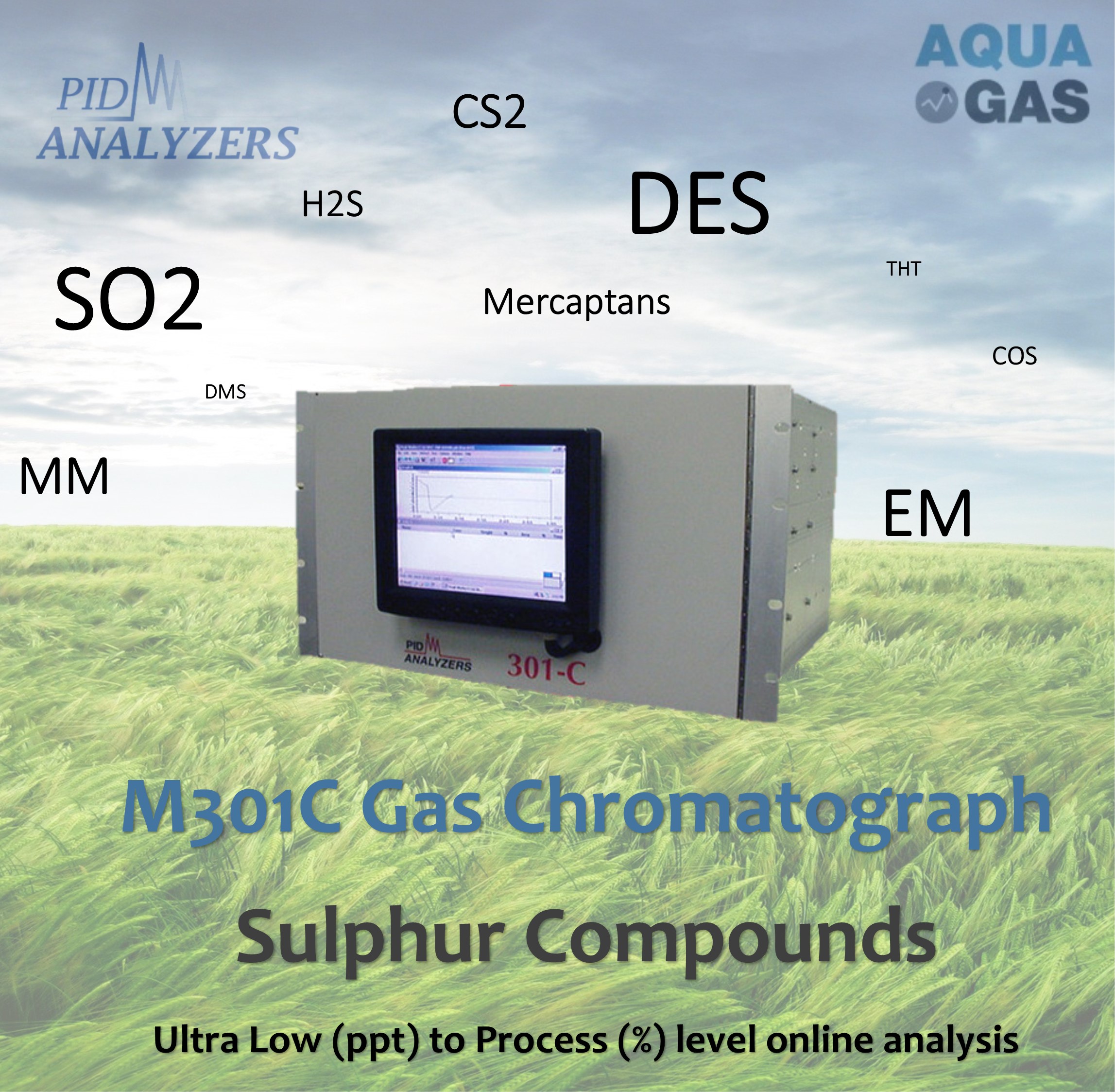

Ideally suited to control biofilters, scrubbers and other odour control systems, WT1® fenceline monitoring system is typically designed to measure continuously the concentration of a wide range of air pollutants and odour precursors including but not limited to H2S, Mercaptans, Amines, NH2, SO2, CO2, CO, CL, C2HO4, H, HCl, HCN, NH3, O3, NO2, PH3, H2S, O2, SO2, CH4, NO, VOC, PM particles from 0,3 to 17 um.

Source identification

Weather correlated AQM data with Temperature, Relative Humidity, wind speed and direction for Dynamic 3D mapping of dispersion plumes and automatic air pollution report with source identification in rural, industrial and urban areas.

AquaGas Pty Ltd

Integrated systems and Customised Services

AquaGas Pty Ltd is committed to deliver turnkey monitoring solutions customised to today’s industrials needs.

ONLINE WATER ANALYSERS

Ammonium, Free or Total Chlorine, Hydrazine, Morphine, Phenol, Sulfates, Colour, Silica, Phosphates (Orthophosphates), Hardness, Aluminium, Chromium VI, Iron, Nickel, Lead, Zinc, TH, Alkalinity, Chlorides, Cyanides, Fluorides, Peracetic acid VFA, CaM…

SERES® online water quality analyser offers multiple sensor and method configurations. Here are the typical measuring parameter calibrated on the TOPAZ unit. For other parameters or different measuring ranges (MR), please consult us.

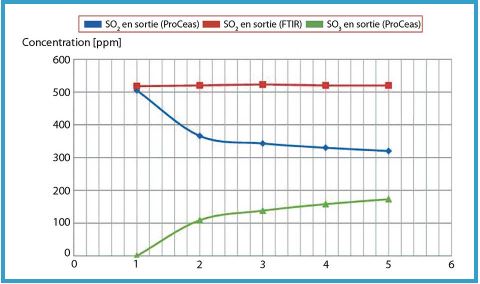

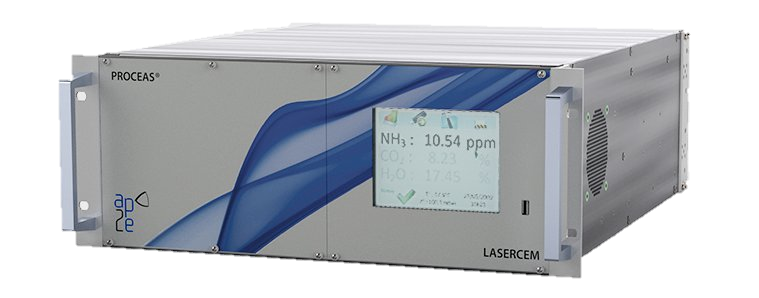

EMISSIONS AND PROCESS GAS ANALYSERS

NO, NO2, NOx, SO2, CO, HCl, CO2, H2O, H2S, NH3, N2O, COS, SO3, CH4, HF, HCN, H2…

Our strong partnerships implemented with world leading CEMS and Process gas analyser manufacturers as well as local distributors, provide AquaGas with an extensive range of technologies, diverse measuring principle and sampling methods to design and build cost effective, versatile and high performance systems composed of instruments specifically selected in consideration of the applications.DATA ACQUISITION AND REPORTING SOFTWARE

Data Aquisition Software (CDAS) is a fully MCERTS accredited (parts A, B, C1 & C2) real time data acquisition software – now available for touch screens and windows 10. CDAS is customisable and flexible, allowing it to collect raw data from a range of instruments for CEMS

ISOKINETIC SAMPLING CONSOLE

Isokinetic sampler developed for short to medium term emissions monitoring, fulfilling all the requirements of the dioxins and persistent organic compounds (POPs), PCBs, metals, HCB and fine dust measurement standard within the same sampling train

HANDHELD and PORTABLE GAS ANALYSERS

O2, CO, CO2, NO, NO2, SO2, H2S, H2, CL2, N2O and VOCs

Professional flue gas analyser combining high quality of sample conditioning with great measurement accuracy for continuous emissions monitoring or online process measurement of up to 9 gases simultaneously.