The SmartCEMS® GH2 is a highly reliable stationary process analyser for green hydrogen gas streams primary constituents (H2 and O2). The SmartCEMS® GH2 is designed for online monitoring of H2 and O2 (other gases available on demand) in GH2 and Hydrocarbon Stream and suits a large field of applications such as upstream or downstream of the electrolyser, at mixing stations or injection points, along the natural gas pipeline and at the end user just upstream of burners plants and associated gas treatment centres.

The SmartCEMS® GH2 was developed through an OEM with Madur (Poland) and is available in Australia and worldwide. Designed to optimise performance/price ratio, the SmartCEMS® GH2 analyser for green hydrogen plants is small in size and measures with a very high level of accuracy. It is the cost effective alternative, for gas chromatograph for instance, in large and complex green hydrogen applications. Its powerful and pleasant PC interface provides operators and system integrators with a broad range of settings to adjust many aspects of the measurement tasks such as automated sampling, calibration, purge sequences, analogue outputs’ behaviour, data presentations… Also, the SmartCEMS® GH2 has been tailored to respond in all aspects to the demanding operating conditions in GH2 applications, thus making it a great and reliable analyser to optimise, operate and maintain plant facilities.

The SmartCEMS® GH2 is offered as a complete stationary CEMS for permanent installation or long term rental. AquaGas global service includes the various level of associated services (initial and final installation, commissioning, long term or punctual service agreement as well as the supply of consumables and critical spares for periods up to 5 years).

| Process analyser for green hydrogen primary constituents in GH2 and hydrocarbon streams (H2 and O2) | Ability to measure gas temperature, velocity and flow. |

| Powerful sensor combinations for complex gas matrices | Pleasant PC interface provide a broad range of settings to adjust many aspects of the measurement tasks such as automated sampling, calibration, purge sequences, analogue outputs’ behaviour. |

| Modular sampling train enabling optimal sampler transfer up to 90metres sampling line | Cost effective compare to typical intricates Biogas monitoring systems (spectrometer, multigas NDIR, Gas Chromatograph). |

| Easy operation and handling, no requirements for purge or zero gas. | Versatile selection of sample gas conditioning method incl. Peltier, Nafion, Compressor |

| Semi-automatic or automatic redundancy for greater data availability and easy Data extraction and processing through Mcerts DAHS computer and CDAS software. | Complies with international standards: EN14181, WA CEMS code, EPAs, NGER |

| Fully supported by AquaGas across Australia, New Zealand and the Pacific Islands (sales and services) | Available in IECEx for installation in Zone 1 explosive gas atmosphere

Dossier of equivalence IECEx/ATEX for AHLX heated sampling train as per relevant Australian Standards. |

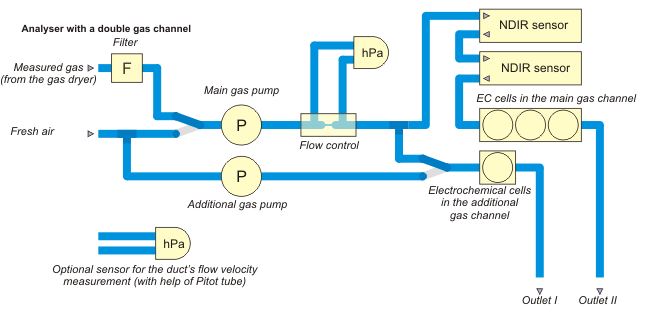

The SmartCEMS® GH2 is a process online analyser for green hydrogen plants designed for continuous and simultaneous measurement of H2 and O2, in a large range of industrial applications including small to large hydrogen production plants, hydrogen and green hydrogen distribution network, H2 fuelled power stations and industrials sites. The combination of technologies (NDIR, TCD, PID, Electrochemical) and the addition of separate gas channels into the same instrument empower flexibility in multigas applications. A unique feature is to allocate a gas channel to sensible sensors. Its design ensures the cells have a limited exposure to gases and therefore extends considerably their respective life-time.

The SmartCEMS® offers multiple sensor and method configurations. Here are the measuring parameter for the most common gases. For other gases or different measuring ranges (MR), please consult us.

| Gas | Analysis Method | Range I Resolution | Accuracy | Time (T90) | Conformity |

|---|---|---|---|---|---|

| O2

Oxygen |

Electrochemical, Partial Pressure | 20.95% |

0.01% |

± 0.1% abs. or 5% rel. | 45 sec | ISO 12039, CTM-030 |

| O2

Oxygen |

Electrochemical, Partial Pressure | 25.00% |

0.01% |

± 0.1% abs. or 5% rel. | 45 sec | ISO 12039, CTM-030 |

| O2

Oxygen |

Electrochemical, Partial Pressure | 100.00% |

0.01% |

± 0.1% abs. or 5% rel. | 45 sec | ISO 12039, CTM-030 |

| CO

Carbon Monoxide |

Electrochemical Sensor | 4 000ppm |

1ppm |

± 5ppm abs. or 5% rel. | 45 sec | ISO 12039, CTM-030 |

| CO

Carbon Monoxide |

Electrochemical, with H2 compensation | 4 000ppm |

1ppm |

± 5ppm abs. or 5% rel. | 45 sec | ISO 12039, CTM-030 |

| CO

Carbon Monoxide |

Electrochemical Sensor | 20 000ppm |

1ppm |

± 5ppm abs. or 5% rel. | 45 sec | ISO 12039, CTM-030 |

| CO

Carbon Monoxide |

Electrochemical, with H2 compensation | 20 000ppm |

1ppm |

± 5ppm abs. or 5% rel. | 45 sec | ISO 12039, CTM-030 |

| CO

Carbon Monoxide |

Electrochemical Sensor | 10% |

0.001% |

± 0.005% abs. or 5% rel. | 45 sec | ISO 12039, CTM-030 |

| CO

Carbon Monoxide |

NDIR

Non Dispersive Infra Red |

10% |

0.01% |

± 0.05% abs. or 5% rel. | 45 sec | EN 15058 and |

| CO

Carbon Monoxide |

NDIR

Non Dispersive Infra Red |

25% |

0.01% |

± 0.05% abs. or 5% rel. | 45 sec | EN 15058 and |

| CO

Carbon Monoxide |

NDIR

Non Dispersive Infra Red |

50% |

0.01% |

± 0.05% abs. or 5% rel. | 45 sec | EN 15058 and |

| CO

Carbon Monoxide |

NDIR

Non Dispersive Infra Red |

100% |

0.1% |

± 0.5% abs. or 5% rel. | 45 sec | EN 15058 and |

| CO2

Carbon Dioxide |

NDIR

Non Dispersive Infra Red |

5% |

0.01% |

± 0.05% abs. or 5% rel. | 45 sec | ISO 12039, |

| CO2

Carbon Dioxide |

NDIR

Non Dispersive Infra Red |

10% |

0.01% |

± 0.05% abs. or 5% rel. | 45 sec | ISO 12039, |

| CO2

Carbon Dioxide |

NDIR

Non Dispersive Infra Red |

25% |

0.01% |

± 0.05% abs. or 5% rel. | 45 sec | ISO 12039, |

| CO2

Carbon Dioxide |

NDIR

Non Dispersive Infra Red |

50% |

0.01% |

± 0.05% abs. or 5% rel. | 45 sec | ISO 12039, |

| CO2

Carbon Dioxide |

NDIR

Non Dispersive Infra Red |

100% |

0.1% |

± 0.5% abs. or 5% rel. | 45 sec | ISO 12039, |

| CxHy

Total Hydrocarbons |

NDIR

Non Dispersive Infra Red |

1% |

0.01% |

± 0.05% abs. or 5% rel. | 45 sec | |

| CxHy

Total Hydrocarbons |

NDIR

Non Dispersive Infra Red |

5% |

0.01% |

± 0.05% abs. or 5% rel. | 45 sec | |

| CxHy

Total Hydrocarbons |

NDIR

Non Dispersive Infra Red |

10% |

0.01% |

± 0.05% abs. or 5% rel. | 45 sec | |

| CxHy

Total Hydrocarbons |

NDIR

Non Dispersive Infra Red |

25% |

0.01% |

± 0.05% abs. or 5% rel. | 45 sec | |

| CxHy

Total Hydrocarbons |

NDIR

Non Dispersive Infra Red |

50% |

0.01% |

± 0.05% abs. or 5% rel. | 45 sec | |

| CxHy

Total Hydrocarbons |

NDIR

Non Dispersive Infra Red |

100% |

0.1% |

± 0.5% abs. or 5% rel. | 45 sec | |

| NO

Nitric Oxide |

Electrochemical Sensor | 1 000ppm |

1ppm |

± 5ppm abs. or 5% rel. | 45 sec | CTM-022 |

| NO

Nitric Oxide |

Electrochemical Sensor | 5 000ppm |

1ppm |

± 5ppm abs. or 5% rel. | 45 sec | CTM-022 |

| NO2

Nitrogen Dioxide |

Electrochemical Sensor | 1 000ppm |

1ppm |

± 5ppm abs. or 5% rel. | 60 sec | CTM-022 |

| NO2

Nitrogen Dioxide |

Electrochemical Sensor | 4 000ppm |

1ppm |

± 5ppm abs. or 5% rel. | 60 sec | CTM-022 |

| SO2

Sulphur Dioxide |

Electrochemical Sensor | 2 000ppm |

1ppm |

± 5ppm abs. or 5% rel. | 45 sec | |

| SO2

Sulphur Dioxide |

Electrochemical Sensor | 5 000ppm |

1ppm |

± 5ppm abs. or 5% rel. | 45 sec | |

| H2S

Hydrogen sulfide |

Electrochemical Sensor | 1 000ppm |

1ppm |

± 5ppm abs. or 5% rel. | 70 sec | |

| H2S

Hydrogen sulfide |

Electrochemical Sensor | 10 000ppm |

1ppm |

± 5ppm abs. or 5% rel. | 45 sec | |

| H2

Hydrogen |

Electrochemical Sensor | 2 000ppm |

1ppm |

± 10ppm abs. or 5% rel. | 50 sec | |

| H2

Hydrogen |

Electrochemical Sensor | 20 000ppm |

1ppm |

± 10ppm abs. or 5% rel. | 70 sec | |

| H2

Hydrogen |

TCD

Thermal Conductivity Detector |

10% |

0.1% |

± 0.5% abs. or 5% rel | 45 sec | |

| H2

Hydrogen |

TCD

Thermal Conductivity Detector |

25% |

0.1% |

± 0.5% abs. or 5% rel | 45 sec | |

| H2

Hydrogen |

TCD

Thermal Conductivity Detector |

50% |

0.1% |

± 0.5% abs. or 5% rel | 45 sec | |

| H2

Hydrogen |

TCD

Thermal Conductivity Detector |

100% |

0.1% |

± 0.5% abs. or 5% rel | 45 sec | |

| N2O

Nitrous Oxide |

NDIR

Non Dispersive Infra Red |

2 000ppm |

1ppm |

± 10ppm abs. or 5% rel | 45 sec | ISO 21258 |

| N2O

Nitrous Oxide |

NDIR

Non Dispersive Infra Red |

5 000ppm |

1ppm |

± 10ppm abs. or 5% rel | 45 sec | ISO 21258 |

| CHF3

Fluoroform (Refrigerant R23) |

NDIR

Non Dispersive Infra Red |

2.5% |

0.01% |

± 0.05 abs. or 5% rel. | 45 sec | |

| CL2

Chlorine |

Electrochemical Sensor | 250ppm |

1ppm |

± 5ppm abs. or 5% rel. | 60 sec | |

| VOC

Volatile Organic Compounds |

PID

Photo Ionization Detector |

100ppm |

1ppm |

± 5ppm abs. or 5% rel. | 120 sec | Method 21 |

| VOC

Volatile Organic Compounds |

PID

Photo Ionization Detector |

1000ppm |

1ppm |

± 5ppm abs. or 5% rel. | 120 sec | Method 21 |

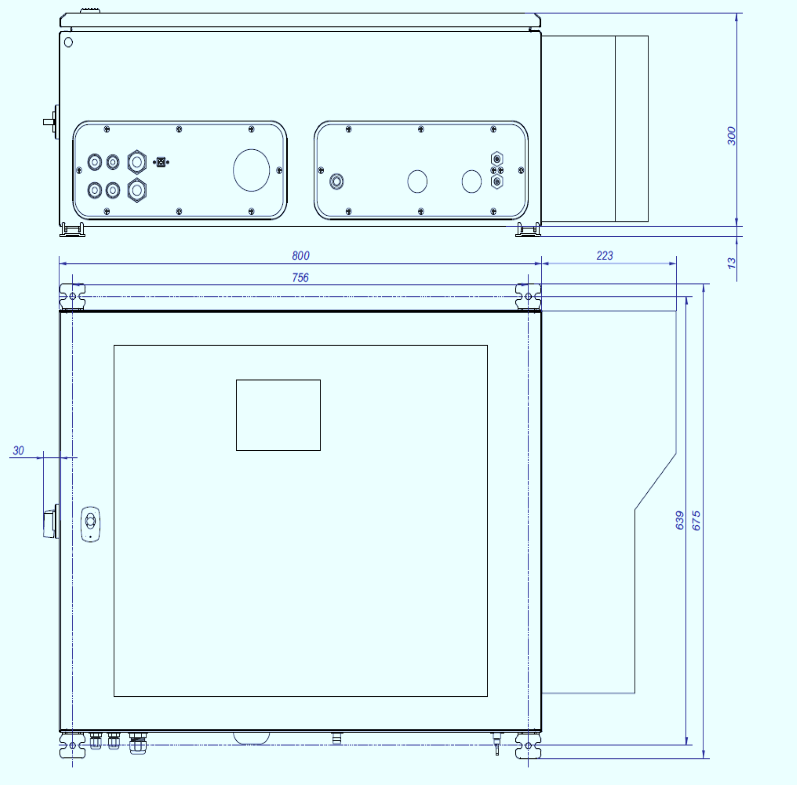

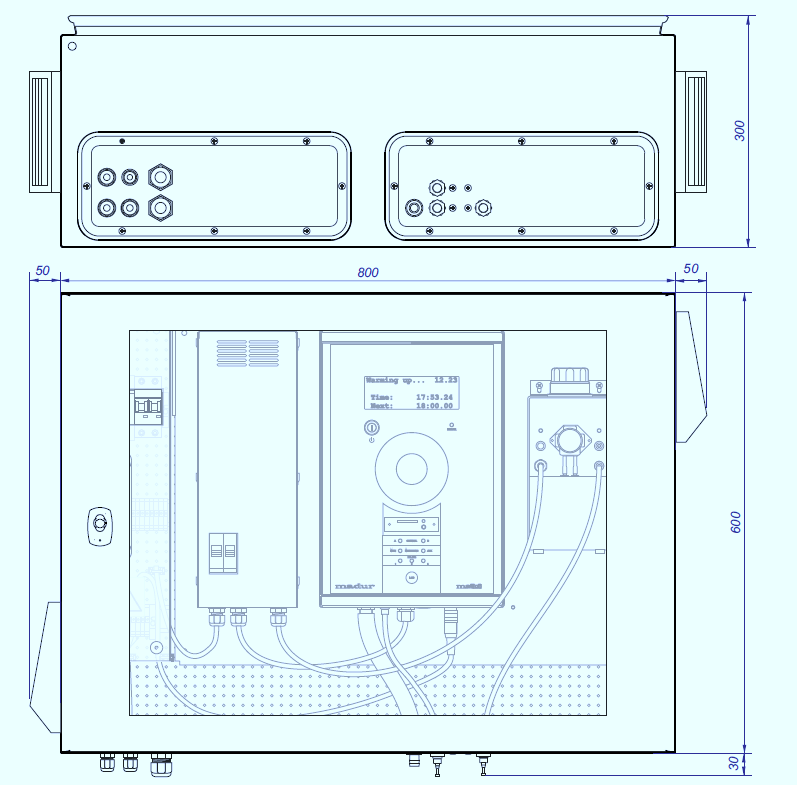

IP55 enclosure with air conditioning unit. Enclosure fitted with terminals, gland plates, power point, circuit breaker and delivered ready for installation outdoor at industrial site.

| Cooling Capacity | 320 W |

| Compressor | Rotary piston compressor |

| Refrigerant | R134a / 1430 |

| High/Low Pressure | 20/13 bar |

| Temperature range | 10°C ÷ 50°C |

| Air volume flow | Ambient 250 m3/h

Cabinet 250 m3/h |

| Mounting | External recessed on enclosure side panel with SS cover |

| Weight and dimensions | 13 kg – 520 x 270 x 110 mm |

| Mains fuse | 6A required. 3,2A at start, max 1.8A / Power 375 W |

Integration in standard IP56 enclosure with forced fan. Enclosure fitted with terminals, gland plates, power point, circuit breaker and delivered ready for installation outdoor at industrial site.

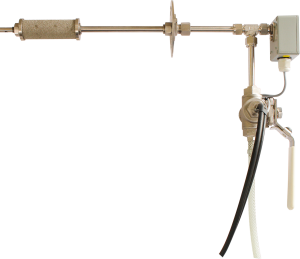

The SmartCEMS® GH2 stationary gas sampling probe has a modular design to fit most of CEMS and Process applications. The Probe configuration can be adapted to the sampling conditions and environment (gas temperature, dust load…). The SmartCEMS® GH2 stationary Gas sampling probe features insitu sintered stainless steel filter, Gas temperature measurement with K-type thermocouple, backflush valve (manual or automatic)to blowback the filter. The SmartCEMS® GH2 stationary gas sampling probe is typically flange mounted directly onto the sampling duct. Once extracted the sample is then directed to the gas conditioning system through heated or unheated sampling line.

The SmartCEMS® GH2 MD3 Gas Conditioning unit is equipped with a condensation dryer based on the Peltier element, built-in peristaltic pump for condensate removal, and large surface particulate filter. The SmartCEMS® GH2 MD3 gas dryer can be supplied mounted onto the same plate than the SmartCEMS® gas analyser or mounted on its own plate with its associated power supply. This allows locating the SmartCEMS® GH2 MD3 gas conditioning unit located directly at the sampling point.

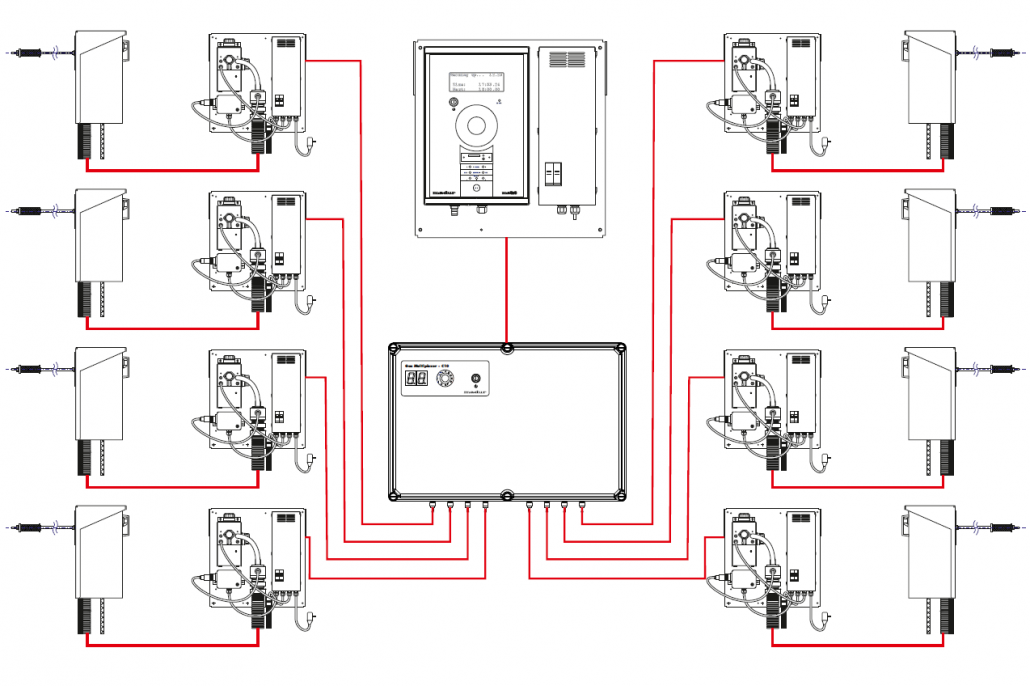

The SmartCEMS® GH2 Gas multiplexer enables sequential monitoring of multiple gas streams. With user configurable sampling sequences, the SmartCEMS multiplexer provides plant operators with the ability to scan GH2 composition across various hydrocarbons gas streams and process locations.

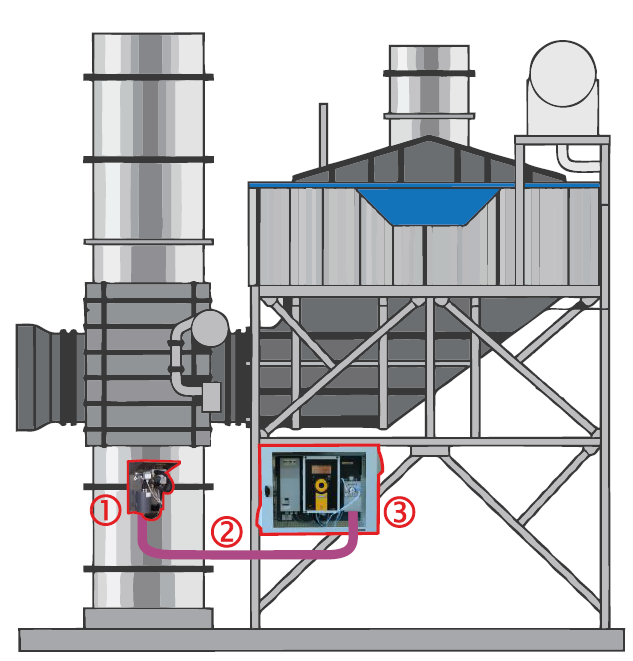

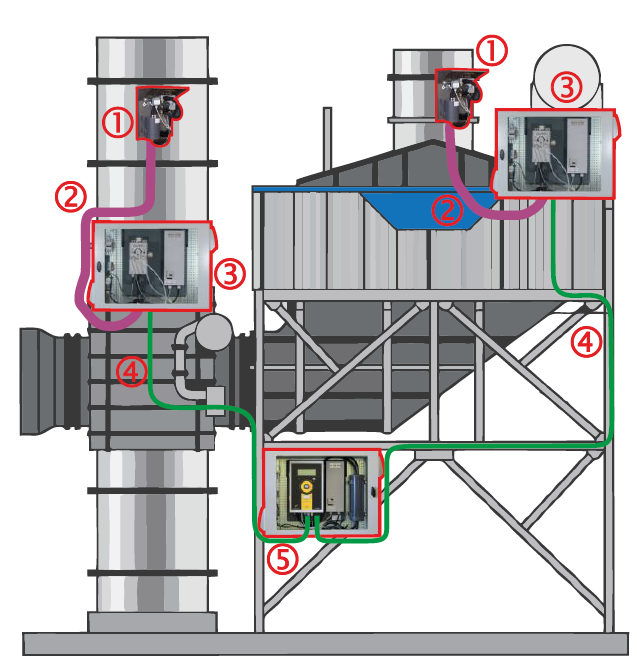

1. Stationary gas sampling probe with optional heated filter, insitu filter and backflush

2. Heated sample line (1 to 5m)

3. SmartCEMS® Multigas Analyzer with MD3 gas conditioning system with Peltier cooler, peristaltic pump and particulate filter with optional IP55 housing.

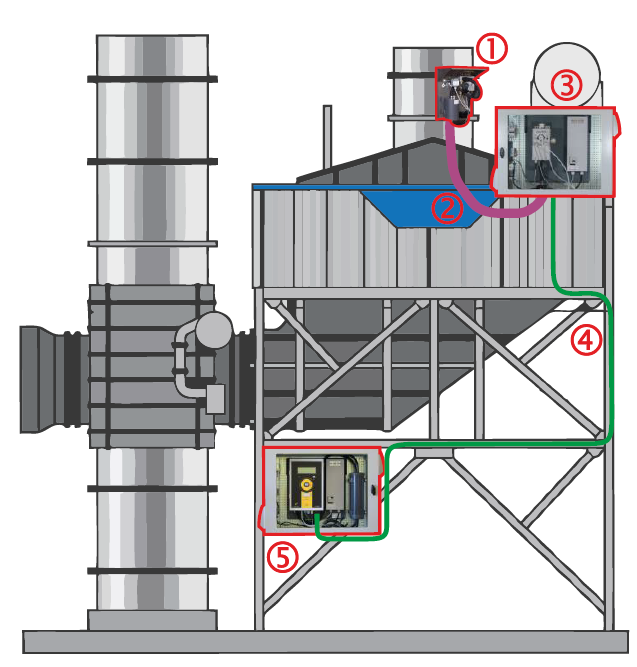

1. Stationary gas sampling probe with optional heated filter, Insitu filter and backflush

2. Heated Sample line short (1 to 3m)

3. MD3 gas conditioning system with Peltier cooler, peristaltic pump and particulate filter installed near the sampling probe assembly and integrated into the AC housing.

4. Dry gas and electric connection cable. Connects gas dryer and SmartCEMS®. Dry gas line can be long, distance up to 100m or longer if necessary.

5. SmartCEMS® Multigas analyser installed in convenient location (e.g. operation shed), may be in remote distance from measurement place. Option available with the IP55.

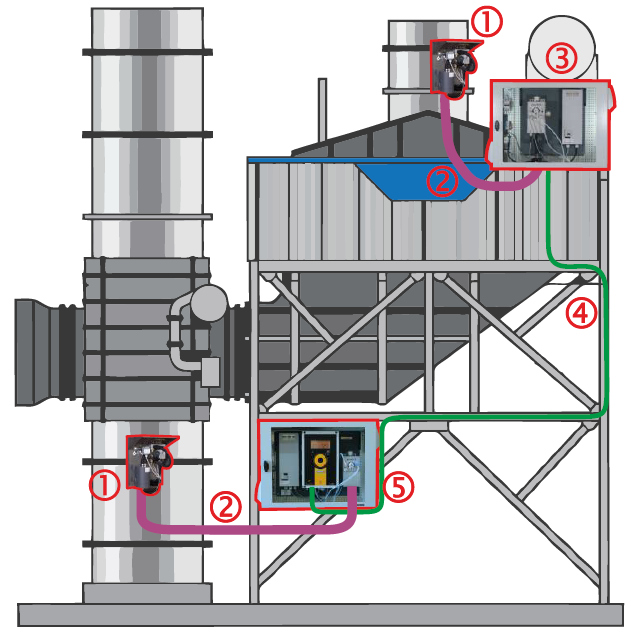

1. Stationary gas sampling probe with optional heated filter, Insitu filter and backflush

2. Heated Sample line short (1 to 3m)

3. MD3 gas conditioning system with Peltier cooler, peristaltic pump and particulate filter installed near the sampling probe assembly and integrated into the AC housing.

4 . Dry gas and electric connection cable. Connects gas dryer and SmartCEMS®. Non-heated line can be up to 100m or longer if necessary.

5. SmartCEMS® Multigas analyser installed in convenient location (e.g. operation shed) with optional IP55 housing

1. Stationary gas sampling probe with optional heated filter, Insitu filter and backflush

2. Heated Sample line short (1 to 3m)

3. MD3 gas conditioning system with Peltier cooler, peristaltic pump and particulate filter installed near the sampling probe assembly and integrated into the AC housing.

4 . Dry gas and electric connection cable. Connects gas dryer and SmartCEMS®. Non-heated line can be up to 100m or longer if necessary.

5. SmartCEMS® Multigas analyser installed in convenient location (e.g. operation shed) with optional IP55 housing

AquaGas Pty Ltd ensure providing support across the Oceania region for maintenance and supply of spares (both hardware & software) as required for the installed system for a minimum period of 20 (twenty) years i.e. the design life of the plant, after successful commissioning of the system.

Depending on your needs, AquaGas Pty Ltd provides adapted services and a technical solution to incorporate Automatic Monitoring Systems (CEMS, AQMS, WQMS, Process Analytics, Gas Detection…) into the mainstream of your existing system or new installation:

- Installation supervision

- Final installation

- Parameterization

- Start-up operation

- Site acceptance testing and performance testing

- System certifications and RATA relative accuracy test audit

Flexible and customised service agreements available on all equipment supplied:

- Accomplishment of preventive and corrective maintenance with pre-set site attendance time

- Dedicated technician

- Email and phone support – remote access

- Supply of spare parts

- Asset management

Instrument network handling:

- Maintenance plan

- Implementation of certification and calibration programs

- Development of data processing systems

- Spare parts stock and system documentation management

- Gas cylinder stock handling

SmartCEMS® – Tailored to TODAY’s monitoring requirements

Typical Applications

Process gas and emissions monitoring in combustion plants, boilers, syngas, biogas, waste recycling facilities (Waste to Energy) and associated filtration systems are typical applications for the SmartCEMS® multiple gas channels configuration.

Landfills

“Landfilling” is the main method for disposal of municipal and household solid wastes or refuses in Australia. Although maintained in an oxygen-free environment and relatively dry conditions, landfill waste produces significant amounts of landfill gas (mostly methane). The Mamos enables process and air pollution emissions monitoring from solid waste landfills. Landfills operations require the control of methane CH4 and non-methane organic compound emissions (NMHC) emitted as well as an accurate online monitoring of the gas composition (CH4, CO, CO2, H2, H2S and O2). This effectively requires the collection and combustion of landfill gases. So, a good solution to the landfill gas problem is to collect it and use it to produce electricity. Landfill gas (LFG)entering the gas sampling system is saturated with water, and that water must be removed prior to further processing. The typical dry composition of the low-Btu gas is 57% CH4, 42% carbon dioxide, 0.5% nitrogen, 0.2% hydrogen, 0 to 1000 ppm of H2S and 0.2%oxygen. In addition, a significant number of other compounds are found in trace quantities. These include alkanes, aromatics, chlorocarbons, oxygenated compounds, other hydrocarbons and sulfur dioxide.

Biogas Plants

In biotechnological processes, the detailed monitoring of the fermentation product, in this case biogas, provides valuable information. Therefore, it is recommended to monitor both the volume of gas produced and the gas composition. With regard to process monitoring, a change in either gas production or gas composition can be an indicator of process imbalance.

Biogas primary constituents

- CH4 and H2S measured during the methanation process give a good overall view of the performance of the degradation process and bacterial activity. A decrease in methane content can be a first sign of organic overload, provided that the feedstock mix has not recently changed. Similarly, a sudden increase in H2S can provoke process instability.

- Simultaneous real-time monitoring of CH4, H2S and CO2 empower process automation (i.e. operation of scrubbers)

- Before entering the distribution chain, the product must be qualified, again for economic reasons (excess H2S and/or CO2 in the CH4 would make it ‘sour’ and potentially corrosive enough to damage distribution infrastructure)

- CH4, H2S, CO, CO2 and O2 Continuous Stack Emissions Monitoring required for environmental compliance

Accuracy and high reliability in harsh conditions of operations makes the SmartCEMS® a powerful optimisation tool for waste recycling facilities (incinerator, water treatment plant).

SCR and SNCR Selective non-catalytic and catalytic reductions are designed to reduce the emissions of NOx by injecting ammonia is directly injected at the combustion chamber exhaust. This process causes the nitrogen oxides to react with the ammonium and turn into nitrogen and water. The SmartCEMS® is suited to upstream and downstream SNCR/SCR monitoring and provides plants operator with accurate data to control NOx regulatory emissions while optimising the denitrification process with upstream NOx measurements.

GTC and flue gas scrubbers reduce the emissions of acid gases such as SO2 with pulverised lime powder or solutions while the discharge of heavy metals and organic pollutants is controlled with the addition of activated carbon. Online monitoring of O2, SO2 upstream of the GTC allows reducing the quantity of reagents injected.

Syngas Plants

The use of process gas online monitoring systems at locations such blast furnace gas outlet, converter off gas exhaust and coking gas outlet is very reasonable in order to analyse the fuel gases composition by measuring the concentration of CO, CO2, O2, N2, CH4, and H2. There from the calorific value BTU and the Wobbe Index WI can be accurately calculated. Modern steel plants uses dedicated stationary online monitoring system to monitor the primary constituents of Direct Reduction Iron process gases essential to have a full understanding of the process status and efficiency.

The realization of the importance of shifting from fossil fuels, both for environmental and energy security reasons, makes the use of green hydrogen extremely pertinent, as one of several potential low-carbon fuels that could take the place of fossil hydrocarbons.

To maintain safe operation, optimise the power to hydrogen conversion, and maximize the quality and purity of the produced hydrogen; the green hydrogen production process relies on measuring multiple parameters as extensively as possible and using the resulting data to inform Plant Operators.

AquaGas online analysers are suited to a large range of applications within the GH2 industry providing real time gas stream composition at key locations:

- Upstream or downstream of the electrolyser

- At mixing stations or injection points

- Along the natural gas pipeline

- At customer sites just upstream of burners

When used to their full extent, the expanded capabilities offered by accurate and reliable analysers can bring real benefits by, optimising efficiency and safety, and providing fast access to detailed data and an accurate real time overview of the operating conditions.