HM-1400 TRX 2

Continuous Mercury Measurement in Stack or Process Gases

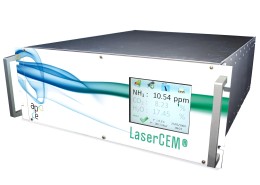

The HM-1400 TRX2 is a the most accurate analyser for continuous mercury measurement in stack or process gases allowing speciation of elemental and oxidised mercury.

The analyser is certified QAL1 according to EN 1567 and has an automatic reference point check with internal reference gas generator. This analyser has shown a great level of reliability in a wide range of applications such as power industry (coal-fired power plants), waste incineration (municipal waste, hazardous waste, sewage sludge), cement industry, steel industry (steelworks with scrap metal reconditioning) and fluorescent light bulb recycling.

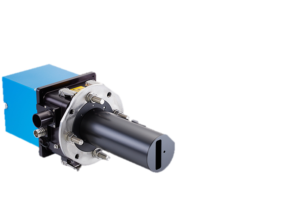

Mercury Analyser

Exclusive Features

HM-1400 TRX 2

| Continuous measurement

HM-1400 TRX 2 allows real-time monitoring of Hg emissions and is therefor suitable for process control and process optimisation. Also smallest certified measuring range 0…15 µg/m3* |

No extremely heated components and Easy to maintain

The HM-1400 TRX 2 does not contain any extremely heated components and includes a fast system cooling and is thereby easy to maintain. Maintenance interval every 3 months |

| Convenient operation

Remote monitoring (off-site and/or through plant control systems) results in minimised technician |

Internal reference gas generator

Automatic reference point check with internal HgCl2 reference gas generator |

| Smallest certified measuring range 0…15 µg/m3*

Stable measured values and maximum of daily |

Measuring principle allows Hg speciation

The Speciation results immediately demonstrate and validate Hg reduction strategies and technologies or effect of alternative fuels |

| Cost savings due to process optimisation and reduced operational costs |

Certified QAL1 according to EN 15267

Type approved according to EN 15267-1, EN 15267-2, EN 15267-3 and EN 14181 |

Specifications

Mercury Analyser

HM-1400 TRX 2

Analytical Performances

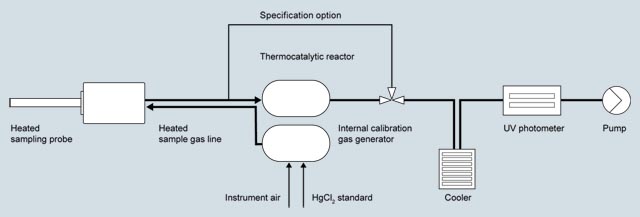

Measuring principle atomic absorption spectroscopy (AAS) with means of a dual beam UV photometer after conversion of oxidised mercury to elemental mercury

Measurements total mercury concentration Hgtotal after calibration with standard reference method

Measuring range Hgtotal

0 … 15 μg/m3,

0 … 400 μg/m3,

0 … 3,000 μg/m3

Certified measuring range 0 … 15 μg/m3 (4), 0 … 45 μg/m3, 0 … 75 μg/m3

Light source & spectral range mercury lamp, 253.7 nm

Pleasant interface

Interface operating panel in front door with display, remote access for DURAG service by TCP/IP as an option

Power Supply 230/400 V 3x25A, N, PE 50 Hz max. 10kVA

Digital Outputs 9x contact NC/NO, function capable of being parameterised

Analog Outputs 3x 4 … 20 mA, max. 500 Ohm, capable of being parameterised

Digital Inputs 8x status input, function capable of being parameterised

Construction

Certification CE and QAL1 EN 15267-1:2009, EN 15267-2:2009, EN 15267-3:2008, EN 14181:2015

Materials Steel cabinet, painted

Weight 220 kg

External dimensions 1700 (W) x 800 (D) x 500 (H) (units: mm)

Measured Parameters

D-R 290

Mercury Analyser using the atomic absorption spectroscopy principle. and accurately measure the total mercury concentration (Hgtotal) or elemental mercury concentration (Hg0)

| MEASURING PARAMETER | RANGE |

|---|---|

| Total mercury concentration | 0 … 15 µg/m3, 0 … 400 µg/m3, 0 … 3.000 µg/m3 (depending on design) |

| Light source and Spectral range | Mercury lamp, 253.7 nm |

| Flue gas temperature | up to 300°C |

| flue gas relative humidity | 0 … 100 % rel. humidity |

| inner duct pressure (gauge) | -50 … +20 hPa |

| Detection limit | 0.015 µg/m³ |

System Components & Applications

HM-1400 TRX2

The HM-1400 TRX 2 is suitable for various applications including power industry (coal-fired power plants), waste incineration (municipal waste, hazardous waste, sewage sludge), cement industry, steel industry (steelworks with scrap metal reconditioning) and fluorescent light bulb recycling.

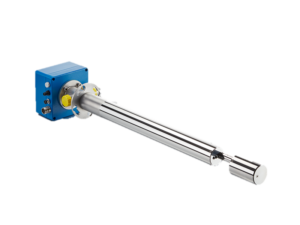

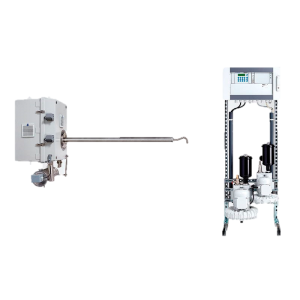

Sampling System

Components

- Sampling probe

- Sampling Tube

- Heated sample gas line

Sampling probe

Sample probe with inside heated filter element and inlet for heated test gas, PT 100 temperature sensor, controlled by HM-1400 TRX 2, 230V L, N, PE 50/60Hz, 650VA

Sampling Tube

variations:

not heated, length 1000 or 1500mm heated, length 180, 600, 1000 or 1500mm

Power 230VAC L,N,PE 600/800/1200 W / PT 100 supplied by HM-1400 TRX 2 (1)

Sampling line

Temperature controlled 200°C heated sample line, IP 65

Power supply 230V L,N,PE, 50-60 Hz, 90-100 W/m

Stack Monitoring Solution

Industrial Stacks

With stricter environmental regulations optimisation of the combustion process for reduced pollutant emission and higher fuel efficiency is a major objective for manufacturers.

Monitoring solutions and applications for stack industries

- Oxygen concentration monitoring, in combustion flue gas to ensure fuel efficiency of the industrial burners.

- Low dust concentration monitoring, to ensure continuous measure and control dust emissions to all stacks industries.

Continuous emission monitoring applicable for a wide range of applications, such as:

- incineration plants

- waste incineration plants

- power plants

- Cement plants

- metal industry

- on plants according to 2001/80/EC LCPD

- on plants according to IED 2010/75/EU

Opacity measurements in flue gas e.g.

- on cruise and container ships

- on plants in accordance with US EPA 40 CFR 60 PS1

Cases Studies

https://www.aquagas.com.au/wp-content/uploads/2022/12/Proceas-Durag-01.png

1398

2481

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2024-03-26 22:59:162024-04-08 20:29:19New ProCeas AIR ref in NSW

https://www.aquagas.com.au/wp-content/uploads/2022/12/Proceas-Durag-01.png

1398

2481

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2024-03-26 22:59:162024-04-08 20:29:19New ProCeas AIR ref in NSW https://www.aquagas.com.au/wp-content/uploads/2024/02/AquaGasAirqual1.png

295

706

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2024-02-15 17:52:212024-02-15 18:09:09Empower Your Safety with AIRQUAL-1

https://www.aquagas.com.au/wp-content/uploads/2024/02/AquaGasAirqual1.png

295

706

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2024-02-15 17:52:212024-02-15 18:09:09Empower Your Safety with AIRQUAL-1 https://www.aquagas.com.au/wp-content/uploads/2023/08/AquaGas-Peracetic-Acid.png

732

1097

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-08-19 22:57:512023-08-19 23:20:48Peracetic Acid Exposure Monitoring

https://www.aquagas.com.au/wp-content/uploads/2023/08/AquaGas-Peracetic-Acid.png

732

1097

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-08-19 22:57:512023-08-19 23:20:48Peracetic Acid Exposure Monitoring https://www.aquagas.com.au/wp-content/uploads/2023/08/AquaGas-Snowy-Mountains-project-scaled-e1691936503389.jpeg

1036

2560

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-08-13 14:20:212023-11-09 12:32:49Two CEMS for a Power Station in NSW

https://www.aquagas.com.au/wp-content/uploads/2023/08/AquaGas-Snowy-Mountains-project-scaled-e1691936503389.jpeg

1036

2560

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-08-13 14:20:212023-11-09 12:32:49Two CEMS for a Power Station in NSW https://www.aquagas.com.au/wp-content/uploads/2023/08/AquaGas-DadoLab-Post-Blog-scaled.jpeg

1440

2560

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-08-05 17:39:432023-08-19 22:47:01Cutting-edge solutions for stack emission and environmental sampling

https://www.aquagas.com.au/wp-content/uploads/2023/08/AquaGas-DadoLab-Post-Blog-scaled.jpeg

1440

2560

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-08-05 17:39:432023-08-19 22:47:01Cutting-edge solutions for stack emission and environmental sampling https://www.aquagas.com.au/wp-content/uploads/2023/07/AquaGas-Chemical-Vapor-Monitoring.png

839

1258

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-07-29 14:46:042023-08-08 22:29:26Air Monitoring for Workplace Safety

https://www.aquagas.com.au/wp-content/uploads/2023/07/AquaGas-Chemical-Vapor-Monitoring.png

839

1258

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-07-29 14:46:042023-08-08 22:29:26Air Monitoring for Workplace Safety https://www.aquagas.com.au/wp-content/uploads/2023/07/AquaGas-Ellona-Paris-odour-control-crop.png

1143

2782

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-07-23 13:39:062023-08-19 22:47:16Smart sensors enhance odour control at Paris waste-to-energy plant

https://www.aquagas.com.au/wp-content/uploads/2023/07/AquaGas-Ellona-Paris-odour-control-crop.png

1143

2782

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-07-23 13:39:062023-08-19 22:47:16Smart sensors enhance odour control at Paris waste-to-energy plant https://www.aquagas.com.au/wp-content/uploads/2023/07/AquaGas_Tocadero-Toc_product.png

1812

2644

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-07-09 21:06:292023-08-19 22:47:29TOCADERO TOC, more accurate and reliable measurements

https://www.aquagas.com.au/wp-content/uploads/2023/07/AquaGas_Tocadero-Toc_product.png

1812

2644

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-07-09 21:06:292023-08-19 22:47:29TOCADERO TOC, more accurate and reliable measurements https://www.aquagas.com.au/wp-content/uploads/2023/07/AquaGas-Veolia-Post-scaled.jpg

1920

2560

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-07-07 22:36:302023-08-19 21:35:51Supply of SmartCEMS for multiple projects in Australia and overseas

https://www.aquagas.com.au/wp-content/uploads/2023/07/AquaGas-Veolia-Post-scaled.jpg

1920

2560

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-07-07 22:36:302023-08-19 21:35:51Supply of SmartCEMS for multiple projects in Australia and overseas https://www.aquagas.com.au/wp-content/uploads/2023/06/AquaGas-SO3-monitor-post.png

1763

5042

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-06-04 11:57:412023-11-30 21:28:15SO3 Monitoring System

https://www.aquagas.com.au/wp-content/uploads/2023/06/AquaGas-SO3-monitor-post.png

1763

5042

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-06-04 11:57:412023-11-30 21:28:15SO3 Monitoring System https://www.aquagas.com.au/wp-content/uploads/2023/04/Post-Tunnel-Sensors.png

630

1255

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-04-15 16:35:492023-12-12 23:08:55Introducing FIVES Pillard Tunnel Sensors

https://www.aquagas.com.au/wp-content/uploads/2023/04/Post-Tunnel-Sensors.png

630

1255

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-04-15 16:35:492023-12-12 23:08:55Introducing FIVES Pillard Tunnel Sensors https://www.aquagas.com.au/wp-content/uploads/2023/04/Post-CEMS.png

303

726

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-04-12 22:28:342023-11-15 23:58:11Continuous Emissions Monitoring Systems

https://www.aquagas.com.au/wp-content/uploads/2023/04/Post-CEMS.png

303

726

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-04-12 22:28:342023-11-15 23:58:11Continuous Emissions Monitoring Systems https://www.aquagas.com.au/wp-content/uploads/2023/04/Aquagas-Blog-Sustainable-Packaging.png

1679

2510

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-04-12 22:26:302023-10-12 20:04:10Mobile CEMS for sustainable packaging

https://www.aquagas.com.au/wp-content/uploads/2023/04/Aquagas-Blog-Sustainable-Packaging.png

1679

2510

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-04-12 22:26:302023-10-12 20:04:10Mobile CEMS for sustainable packaging https://www.aquagas.com.au/wp-content/uploads/2023/04/Aquagas-Multi-Metal-Smelter3.png

630

1255

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-04-12 22:16:162023-05-19 09:12:23Multi-metal smelter partners with AquaGas

https://www.aquagas.com.au/wp-content/uploads/2023/04/Aquagas-Multi-Metal-Smelter3.png

630

1255

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-04-12 22:16:162023-05-19 09:12:23Multi-metal smelter partners with AquaGas https://www.aquagas.com.au/wp-content/uploads/2023/04/Aquagas-Blog-Fertilising-Plant.png

684

2510

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-04-12 21:53:552023-10-12 20:44:24AquaGas SmartCEMS at the largest fertilisers plant

https://www.aquagas.com.au/wp-content/uploads/2023/04/Aquagas-Blog-Fertilising-Plant.png

684

2510

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-04-12 21:53:552023-10-12 20:44:24AquaGas SmartCEMS at the largest fertilisers plant https://www.aquagas.com.au/wp-content/uploads/2023/04/Aquagas-Ellona-Copper-facility.jpg

953

1429

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-04-03 22:54:122023-08-19 20:31:26NH3 AQMS in South Australia

https://www.aquagas.com.au/wp-content/uploads/2023/04/Aquagas-Ellona-Copper-facility.jpg

953

1429

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-04-03 22:54:122023-08-19 20:31:26NH3 AQMS in South Australia https://www.aquagas.com.au/wp-content/uploads/2023/04/Aquagas-Ellona-Copper-mine.jpg

882

1920

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-04-03 22:39:112023-07-29 13:00:138 AQMS for a Copper Mine

https://www.aquagas.com.au/wp-content/uploads/2023/04/Aquagas-Ellona-Copper-mine.jpg

882

1920

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-04-03 22:39:112023-07-29 13:00:138 AQMS for a Copper Mine https://www.aquagas.com.au/wp-content/uploads/2022/10/Screenshot-2022-10-03-at-23.35.03.png

769

1152

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-04-03 22:23:002023-07-29 12:53:59IAQ Sensors for Chemical Facilities in QLD

https://www.aquagas.com.au/wp-content/uploads/2022/10/Screenshot-2022-10-03-at-23.35.03.png

769

1152

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-04-03 22:23:002023-07-29 12:53:59IAQ Sensors for Chemical Facilities in QLD https://www.aquagas.com.au/wp-content/uploads/2023/04/Aquagas-Ellona-Offices-and-Warehouses-across-Australia-scaled.jpg

1440

2560

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-04-03 22:13:532023-07-29 12:46:19Indoor air quality in offices and warehouses

https://www.aquagas.com.au/wp-content/uploads/2023/04/Aquagas-Ellona-Offices-and-Warehouses-across-Australia-scaled.jpg

1440

2560

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-04-03 22:13:532023-07-29 12:46:19Indoor air quality in offices and warehouses https://www.aquagas.com.au/wp-content/uploads/2023/04/Aquagas-Ellona-Distributor.png

1340

2001

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-04-03 21:52:192023-07-29 12:26:11Ellona Distributor for Australia

https://www.aquagas.com.au/wp-content/uploads/2023/04/Aquagas-Ellona-Distributor.png

1340

2001

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-04-03 21:52:192023-07-29 12:26:11Ellona Distributor for Australia https://www.aquagas.com.au/wp-content/uploads/2022/12/GHG_contract.png

1080

1920

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2022-12-18 19:31:092022-12-22 19:39:17Greenhouse Gases (GHG) Fugitive Emissions

https://www.aquagas.com.au/wp-content/uploads/2022/12/GHG_contract.png

1080

1920

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2022-12-18 19:31:092022-12-22 19:39:17Greenhouse Gases (GHG) Fugitive Emissions https://www.aquagas.com.au/wp-content/uploads/2022/12/GH2_contract.png

1080

1920

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2022-12-18 19:16:332023-03-13 22:23:16SmartCEMS® GH2 deployed @ multiple GH2 facilities across Australia

https://www.aquagas.com.au/wp-content/uploads/2022/12/GH2_contract.png

1080

1920

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2022-12-18 19:16:332023-03-13 22:23:16SmartCEMS® GH2 deployed @ multiple GH2 facilities across Australia https://www.aquagas.com.au/wp-content/uploads/2022/12/UQ-1038x555-1.png

555

1038

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2022-12-16 00:18:192022-12-22 19:57:00SmartCEMS® GHG

https://www.aquagas.com.au/wp-content/uploads/2022/12/UQ-1038x555-1.png

555

1038

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2022-12-16 00:18:192022-12-22 19:57:00SmartCEMS® GHG https://www.aquagas.com.au/wp-content/uploads/2022/12/Aquagas-Thank-You.png

1080

1920

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2022-12-15 23:34:242022-12-21 13:54:07A note of thanks

https://www.aquagas.com.au/wp-content/uploads/2022/12/Aquagas-Thank-You.png

1080

1920

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2022-12-15 23:34:242022-12-21 13:54:07A note of thanks https://www.aquagas.com.au/wp-content/uploads/2022/12/Aquagas-Happy-New-Year.png

1081

1921

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2022-12-15 22:34:272023-01-01 19:31:58Warmth, joy, and peace from our crew to yours!

https://www.aquagas.com.au/wp-content/uploads/2022/12/Aquagas-Happy-New-Year.png

1081

1921

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2022-12-15 22:34:272023-01-01 19:31:58Warmth, joy, and peace from our crew to yours! https://www.aquagas.com.au/wp-content/uploads/2022/11/GH2-Cycle-3_website.png

1763

4168

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2022-11-16 00:24:382022-12-21 13:54:53PROCEAS® in GH2 Plants

https://www.aquagas.com.au/wp-content/uploads/2022/11/GH2-Cycle-3_website.png

1763

4168

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2022-11-16 00:24:382022-12-21 13:54:53PROCEAS® in GH2 Plants https://www.aquagas.com.au/wp-content/uploads/2022/11/Banner-AquaGas-4-scaled.jpg

931

2560

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2022-11-15 00:02:252022-12-22 19:55:11SmartCEMS® in GH2 Plants

https://www.aquagas.com.au/wp-content/uploads/2022/11/Banner-AquaGas-4-scaled.jpg

931

2560

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2022-11-15 00:02:252022-12-22 19:55:11SmartCEMS® in GH2 Plants https://www.aquagas.com.au/wp-content/uploads/2022/11/GH2-Cycle-3_website.png

1763

4168

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2022-11-14 23:03:572022-12-21 13:55:52GREEN HYDROGEN [GH2]

https://www.aquagas.com.au/wp-content/uploads/2022/11/GH2-Cycle-3_website.png

1763

4168

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2022-11-14 23:03:572022-12-21 13:55:52GREEN HYDROGEN [GH2]

https://www.aquagas.com.au/wp-content/uploads/2016/05/MAMOS-Multigas-analyser-CEMS.jpg

2247

2295

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2018-11-03 07:11:482022-12-20 11:48:03AquaGas SmartCEMS® solution

https://www.aquagas.com.au/wp-content/uploads/2016/05/MAMOS-Multigas-analyser-CEMS.jpg

2247

2295

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2018-11-03 07:11:482022-12-20 11:48:03AquaGas SmartCEMS® solution https://www.aquagas.com.au/wp-content/uploads/2018/04/Woehler_A-550_Industrial_INT-1.jpg

1334

1999

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2018-09-13 05:24:162022-12-15 22:26:41A 550 Industrial Handheld Analyser

https://www.aquagas.com.au/wp-content/uploads/2018/04/Woehler_A-550_Industrial_INT-1.jpg

1334

1999

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2018-09-13 05:24:162022-12-15 22:26:41A 550 Industrial Handheld Analyser https://www.aquagas.com.au/wp-content/uploads/2018/09/Stack-testing-AquaGas-Pty-Ltd.jpg

1035

2552

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2018-09-13 03:46:422022-10-05 22:19:06NOx Emissions Testing

https://www.aquagas.com.au/wp-content/uploads/2018/09/Stack-testing-AquaGas-Pty-Ltd.jpg

1035

2552

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2018-09-13 03:46:422022-10-05 22:19:06NOx Emissions Testing https://www.aquagas.com.au/wp-content/uploads/2018/09/Banner_Airqual.png

524

1500

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2018-09-13 03:13:282024-01-19 00:50:08Breathing Air Quality

https://www.aquagas.com.au/wp-content/uploads/2018/09/Banner_Airqual.png

524

1500

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2018-09-13 03:13:282024-01-19 00:50:08Breathing Air Quality https://www.aquagas.com.au/wp-content/uploads/2018/09/OPENPITATNIGHT.png

713

1600

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2018-09-13 02:23:232022-10-05 22:17:42Flammable and toxic Offgas

https://www.aquagas.com.au/wp-content/uploads/2018/09/OPENPITATNIGHT.png

713

1600

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2018-09-13 02:23:232022-10-05 22:17:42Flammable and toxic Offgas https://www.aquagas.com.au/wp-content/uploads/2018/08/GOLD-COAST-AUSTRALIA.jpg

736

1494

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2018-08-02 05:38:082022-10-05 22:52:20City Of Gold Coast

https://www.aquagas.com.au/wp-content/uploads/2018/08/GOLD-COAST-AUSTRALIA.jpg

736

1494

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2018-08-02 05:38:082022-10-05 22:52:20City Of Gold Coast https://www.aquagas.com.au/wp-content/uploads/2018/08/Clean-Air-AquaGas.jpg

1000

1920

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2018-08-02 04:57:012022-10-05 22:25:23Odour Control Systems

https://www.aquagas.com.au/wp-content/uploads/2018/08/Clean-Air-AquaGas.jpg

1000

1920

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2018-08-02 04:57:012022-10-05 22:25:23Odour Control Systems

https://www.aquagas.com.au/wp-content/uploads/2022/09/E3_site.png

524

1500

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2018-07-30 03:03:372022-12-15 22:30:20WT1 Fence Line Monitoring Solution

https://www.aquagas.com.au/wp-content/uploads/2022/09/E3_site.png

524

1500

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2018-07-30 03:03:372022-12-15 22:30:20WT1 Fence Line Monitoring Solution

https://www.aquagas.com.au/wp-content/uploads/2015/03/slide1.jpg

314

1300

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2017-04-12 03:45:312022-10-10 22:22:39More on AquaGas.com.au

https://www.aquagas.com.au/wp-content/uploads/2015/03/slide1.jpg

314

1300

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2017-04-12 03:45:312022-10-10 22:22:39More on AquaGas.com.au https://www.aquagas.com.au/wp-content/uploads/2017/04/sydney-AquaFID-CEMS.jpg

400

1200

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2017-04-12 03:25:292022-10-10 22:28:36AquaFID THC CEMS – Continuous Emissions Monitoring Systems

https://www.aquagas.com.au/wp-content/uploads/2017/04/sydney-AquaFID-CEMS.jpg

400

1200

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2017-04-12 03:25:292022-10-10 22:28:36AquaFID THC CEMS – Continuous Emissions Monitoring Systems

https://www.aquagas.com.au/wp-content/uploads/2016/05/1217512_shortfin-barracuda-le-nouveau-sous-marin-phare-de-dcns-web-tete-021878385540.jpg

533

1000

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2016-05-15 00:41:552023-03-06 22:16:26Indoor air quality

https://www.aquagas.com.au/wp-content/uploads/2016/05/1217512_shortfin-barracuda-le-nouveau-sous-marin-phare-de-dcns-web-tete-021878385540.jpg

533

1000

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2016-05-15 00:41:552023-03-06 22:16:26Indoor air quality

https://www.aquagas.com.au/wp-content/uploads/2015/12/Nickelhub__014_-scaled.jpg

1707

2560

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2016-01-14 11:04:022023-03-06 23:07:02Process monitoring in biogas plants

https://www.aquagas.com.au/wp-content/uploads/2015/12/Nickelhub__014_-scaled.jpg

1707

2560

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2016-01-14 11:04:022023-03-06 23:07:02Process monitoring in biogas plants https://www.aquagas.com.au/wp-content/uploads/2015/10/chemical_carousel.jpg

486

1296

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2015-10-20 10:22:412023-03-13 22:50:46Online analysis in the Chlorine industry

https://www.aquagas.com.au/wp-content/uploads/2015/10/chemical_carousel.jpg

486

1296

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2015-10-20 10:22:412023-03-13 22:50:46Online analysis in the Chlorine industry

SERVICES & PRODUCTS ENQUIRIES

PRODUCTS

PARTNERS

APPLICATIONS

- New ProCeas AIR ref in NSW

- Empower Your Safety with AIRQUAL-1

- Peracetic Acid Exposure Monitoring

- Two CEMS for a Power Station in NSW

- Cutting-edge solutions for stack emission and environmental sampling

- Air Monitoring for Workplace Safety

- Smart sensors enhance odour control at Paris waste-to-energy plant

- TOCADERO TOC, more accurate and reliable measurements