OFCEAS & Low Pressure Sampling

Starting in 2012, AP2E launched the industrialisation of the ProCeas® and LaserCEM® product range, the continuous and multigas analysers using OFCEAS* patented laser spectrometry. This analyser range is based on several innovations, providing very high performance in terms of response time (less than a few seconds) and great accuracy of the analyses (wide dynamic range from ppb to %):

OFCEAS, CONTINUOUS INFRA-RED LASER SPECTROSCOPY TECHNOLOGY

The ProCeas® and the LaserCEM® are based on the OFCEAS coupled to a Low Pressure Sampling LPS (100 mbar absolute) developed and patented worldwide by AP2E (France), for the online analysis of several key gases in industrial, environmental and OH&S applications. It provides measurements with a very high spectral resolution in addition to an analysis system with a simplified sampling (no heated line nor treatment of samples) and an interference-free, fast and sensitive analysis, regardless of the matrix of the gas to be analysed.

The OFCEAS technology essentially differs from the CRDS (Cavity Ring Down Spectroscopy or Spectroscopy by resonance damping time) technology by its feedback principle: a part of the emitted radiation is returned from the chamber to the laser, enabling the tuning of the laser and the cavity resulting a resonance phenomenon. With a volume of only 15 cm3, the measuring cavity or cell is equipped with mirrors whose reflectivity exceeds 99.99%, providing an optical path between 1 and 10 km (approx. 10 meters in conventional technologies). The immediate consequence of this phenomenon is the identification of very intense absorption peaks with a very narrow spectral width. Given that the source used is a continuous laser, the system presents very high measurement stability: there is no zero drift and no need for new calibrations.

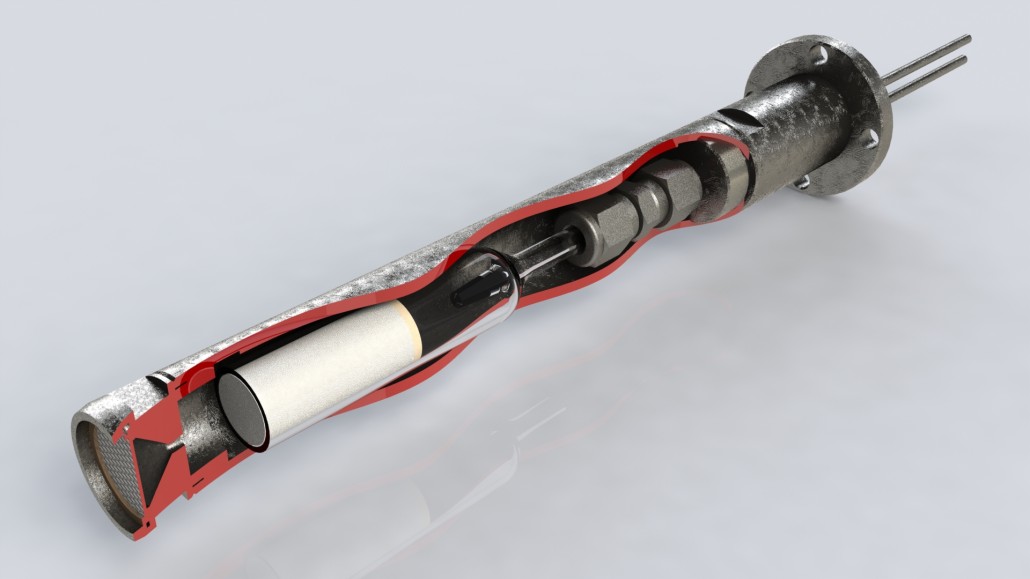

LOW-PRESSURE SAMPLING SYSTEM

The Low Pressure Sampling (LPS) System allows reducing the sample dew point (vapour pressure) to prevent the risk of condensation. The sampling method is achieved by the use of a sonic nozzle which allows reducing the sampling pressure down to 100 mbar. In these conditions the ambient temperature is almost always above the dew point eliminating the risk of condensation.

- No Sample heated line required to eliminate condensation: low power consumption, no related ongoing maintenance

- True Direct Extractive CEMS/Process analyser (no dryer or scrubber)

- No risk of absorption/desorption typical of high SO2/SO3 application

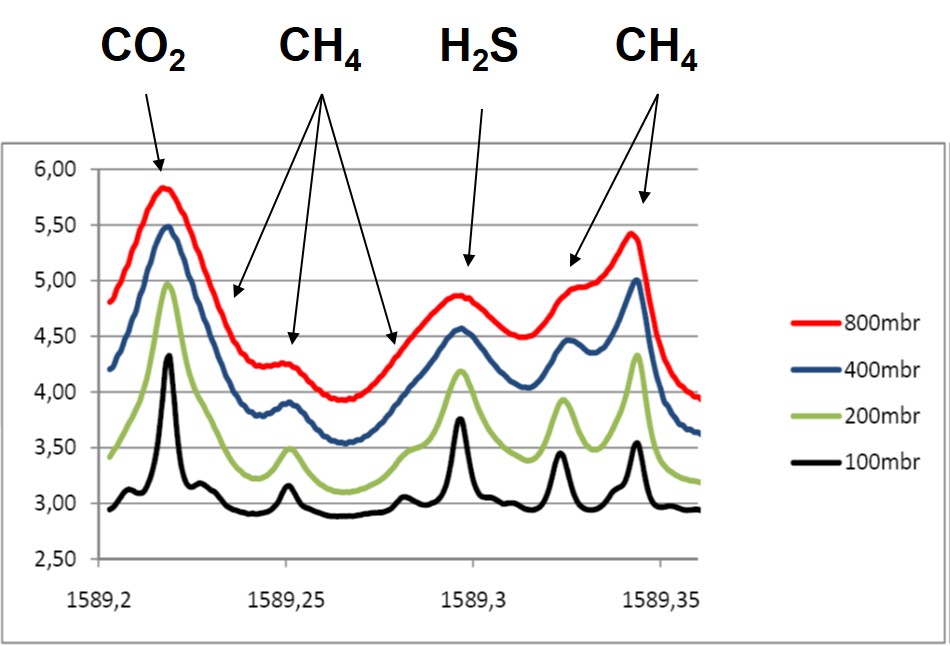

- Low pressure accentuate the gas finger print

- Cost effective multipoint monitoring

- Standard system comply with ATEX standards

The integrity of the sample is therefore ensured. The very low airflow ensures a verylow response time and a minimal contamination of the system.

All these points enable to both increase the detection sensitivity and simultaneously reduce the noise, which permits the detection of gases at very low levels of sensitivity (traces of H2S – LOD under 50 ppb, or traces of H2O – under 1 ppm).

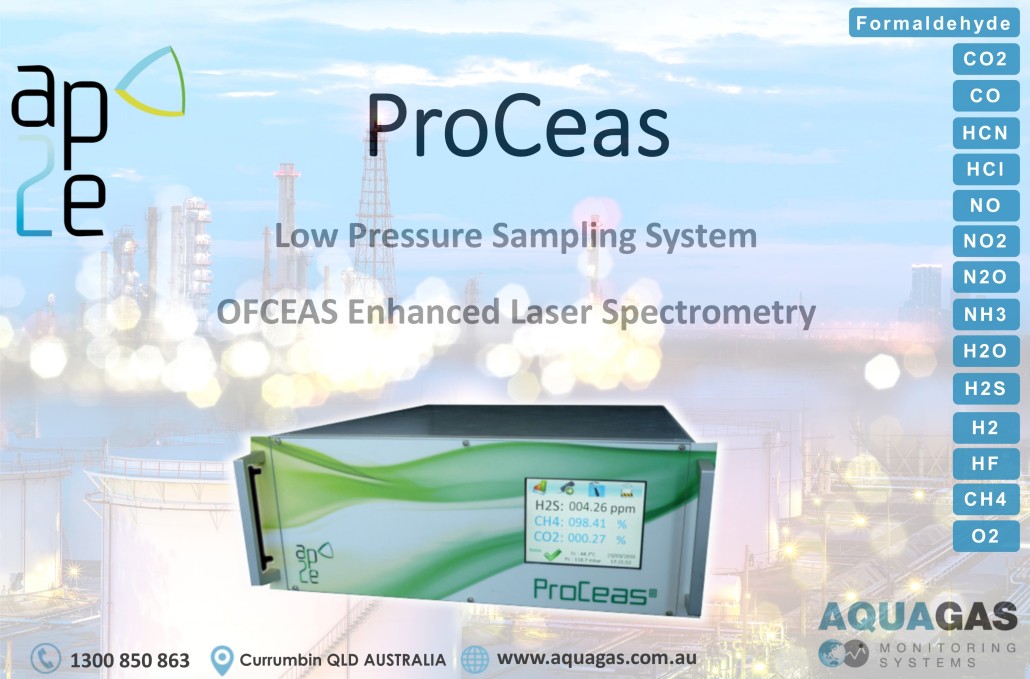

ProCeas

Complete pre-calibrated multicomponent (H2S, CO, CO2, H2, H2O, HCl, HCN, HF, N2O, NH3, O2 and CH4) laser Infrared Spectrometer designed for online monitoring of combustion process, natural gas (LNG), pure gas (trace) and ambient air (trace).

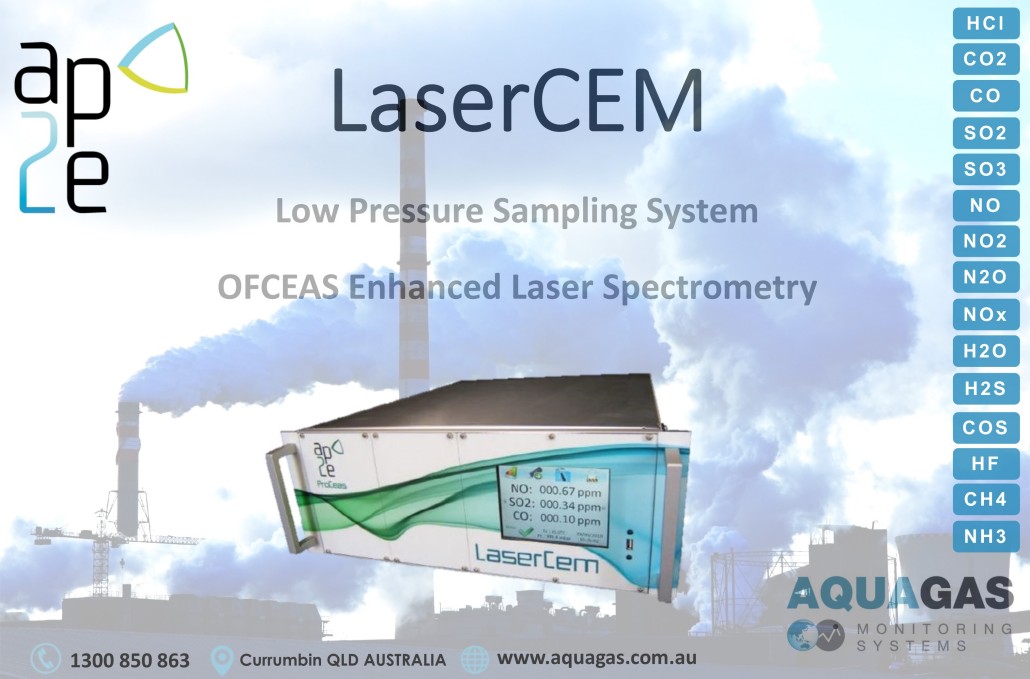

LaserCEM

The LaserCEM is a complete pre-calibrated multi-component (NO, NO2, NOx, SO2, CO, HCl, CO2, H2O, H2S, NH3, N2O, COS, SO3, CH4, HF) laser Infrared Spectrometer designed for Continuous Emissions Monitoring and compliant to standard EN 15267-3 : 2008 and QAL 1 de EN 14181 . With the announcement of the continuous measurement of SO3 (sulphur trioxide) at the exit of combustion units, AP2E represents the link from an industrial point of view between regulatory measurements (EMC) and optimizing production processes. If SO2 is now properly measured, it does not fully reflect the sulphur emissions from combustion units subject to this requirement. In the presence of oxygen, SO2 does in effect form sulphur trioxide (SO3), a gas that is much more corrosive than SO2. And other chemical phenomena occur, particularly in de-nitrification (DeNOx), which in the presence of ammonia may lead both to an over-consumption of ammonia and to filter blockages. Not measuring SO3 entails the under estimation of sulphur emissions, and also additional maintenance costs and over-consumption of reagents. To have continuous and precise knowledge of the SO2 / SO3 couple enables the operator to choose the controlling conditions for limiting the formation of SO3 and its indirect costs.

*Optical Feedback Cavity Enhanced Absorption Spectroscopy: technology developed and patented by the University Joseph Fourier (France), coupled to a Low Pressure Sampling (100 mbar absolute) developed and patented worldwide by AP2E, for the on-line analysis of different gases. By the end of 2010, after two years of R & D studies, the AP2E ProCeas® was the award recipient of the USA “R & D 100” which rewards the 100 most innovative global technologies of the year.