Committed to a better environment and a sustainable future, AquaGas Pty Ltd is delighted to announce its new partnership with one of the leading manufacturer of water quality sensors and monitoring solutions. AquaGas Pty Ltd has recently been appointed by HORIBA as exclusive sales and technical representative for the extensive range of industrial water quality sensors and online analysers.

HORIBA manufactures and sells automotive emission measurement systems, environmental measuring instruments, wide range of scientific analyzers, and medical diagnostic analyzers, and measuring equipment used in the semiconductor industry. HORIBA also manufactures and markets peripheral measuring and analysis devices. Moreover, the Company equips such facilities as laboratories with measuring and analytical equipment for R&D, production, and other applications.

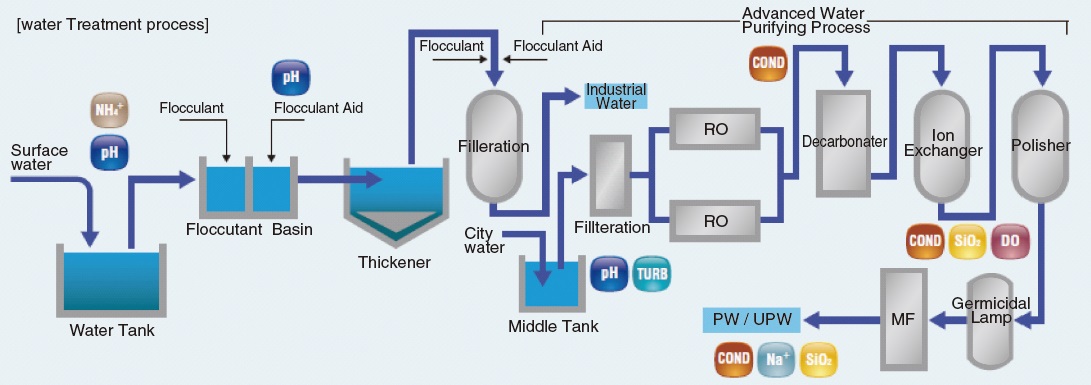

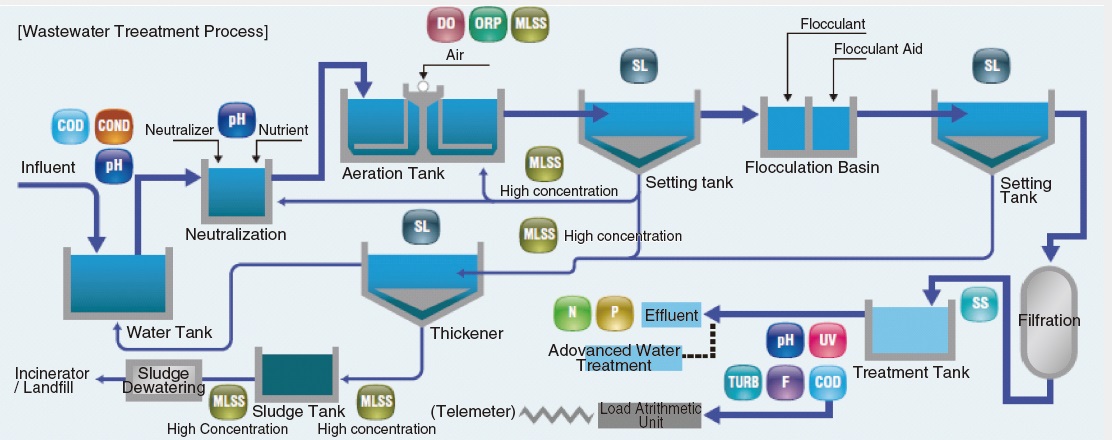

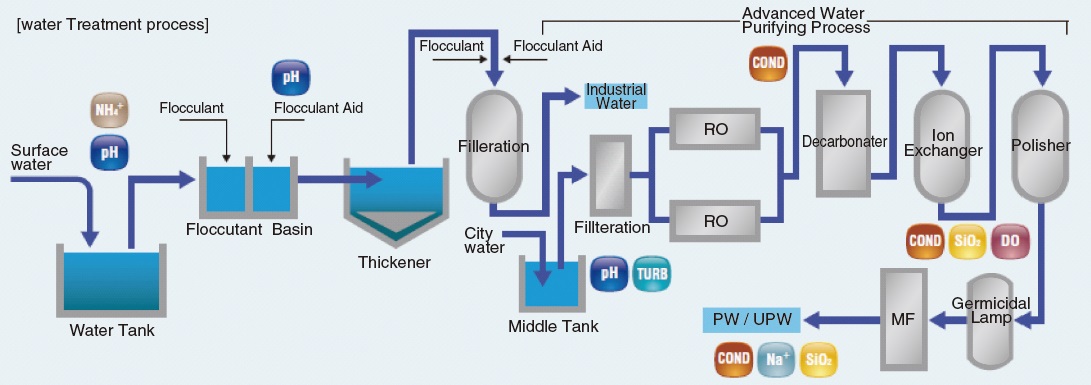

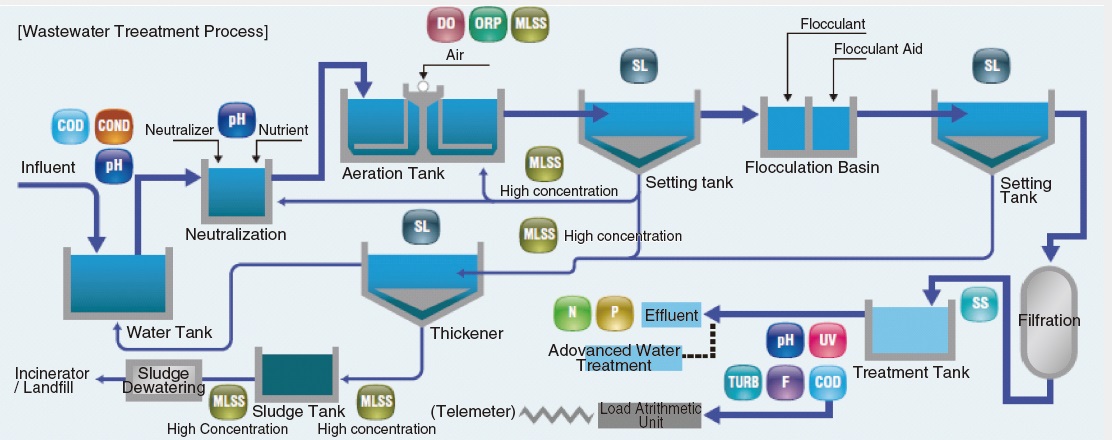

The integration of HORIBA Process and Environmental product range enables AquaGas to respond, with a broad selection of field sensors (H-1® and SLIM 48/96® Series) for the automation of industrial processes, to the growing demand for smart and cost effective monitoring solutions within the water treatment industry. HORIBA wet chemistry and optical (UV and IR) based instruments allow efficient and homogeneous system integration for environmental monitoring and industrial process automations with the choice of 25+ models covering essential water quality parameters such as pH, dissolved oxygen, oxidation-reduction potential, fluoride ion, electrical conductivity, electrical resistance, MLSS, turbidity, free residual chlorine, COD, TP, TN, Oil film and Oil contamination and more.

pH, dissolved oxygen, oxidation-reduction potential, fluoride ion, electrical conductivity,

H-1® and SLIM 48/96® Series comprehensive range of Water Quality Sensors suited to all kinds of water treatment from purified water to wastewater.

WTP water treatment plant

Wastewater treatment plant

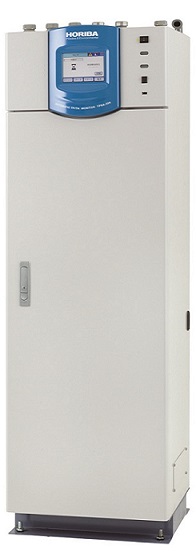

CODA-500®: High-performance Automatic COD Analyser. Tailored to the needs of environmental authorities and plant operators the CODA-500® is designed for the automation of industrial processes.

Advances technologies based on 30 years of accumulated expertise, HORIBA.

Total Nitrogen/Phosphorus

TPNA-500®, a state-of-the-art Total Nitrogen/Phosphorus Analyser adopting 60 years of water measurement technology

Everything from precise measurement to reduced running costs. HORIBA leading the world in practical environmental analysis technology will give a benefit for Total Nitrogen/Phosphorus monitoring.

HORIBA TW-100® Drinking Water Analyser is a process

water quality monitoring system designed for drinking water and water distribution plants. The

TW-100® Drinking Water Analyser uses a reagent free method for online monitoring of

turbidity, color, free chlorine and pressure resulting in a significant reduction of the ownership costs.

TW-100® Drinking Water Analyser is a field proven device that requires minimal maintenance and improves process control.

Organic Pollutant Analyser

OPSA-150® is a new Organic Compounds and Persistent Organic Pollutant Analyser that uses HORIBA’s proprietary Rotary Cell Length Modulation, a measuring technique incorporating 25 years of expertise. The OPSA can be used as an organic pollutant monitor at drainage systems for determining compliance with COD monitoring regulations, for monitoring quality of water measuring levels of organic matter at water supply intakes, and as an organic monitor on process lines (phenol meter).

*Pole mount, outdoor cover, and analysis panel are available as options.

More…

LO-300® Laser scanning Oil Film Detector is a laser based Oil Pollution Analyser designed for on-line detection of oil leakage.

LO-300® Laser scanning Oil Film Detector, scans water surface with its built in laser to detect the presence of oil films on water surfaces and groundwaters. TheLO-300® detects floating oil by sensing the difference in the intensity of reflection between water and oil. As compared with spotlight-based systems, the LO-300® adopted laser scanning method prevents interferences from water surface level fluctuation, and changes in distance between the water surface and the detector.

More…