Continuous Emissions Monitoring Systems

AquaGas Pty Ltd is a leading provider of Continuous Emissions Monitoring Systems (CEMS) for a wide range of industries, including power generation, oil, gas, chemicals, and pharmaceuticals. CEMS are a critical component of environmental monitoring and compliance programs, enabling companies to measure and report their emissions accurately and efficiently.

CEMS technology has come a long way since its inception in the 1970s. Today Continuous Emissions Monitoring Systems are highly sophisticated, using advanced sensors and software to provide real-time data on emissions of pollutants such as nitrogen oxides, sulphur dioxide, carbon monoxide, and particulate matter. This data is essential for regulatory compliance, as well as for identifying opportunities to improve process efficiency and reduce emissions.

AquaGas Pty Ltd offers a range of Continuous Emissions Monitoring Systems to meet the specific needs of its clients. These include.

- Extractive CEMS | These systems use a probe to extract a sample of flue gas from a stack or duct and send it to an analyser for measurement.

- In-Situ CEMS | These systems measure emissions directly in the stack or duct, without the need for sample extraction.

- Dilution CEMS | These systems mix a sample of flue gas with clean air to dilute the pollutants and make them easier to measure.

All these systems rely on advanced sensors and analyzers to measure emissions accurately and reliably. AquaGas Pty Ltd works with leading manufacturers to ensure that its CEMS solutions meet environmental standards and codes in place in Australian states, New Zealand, and Pacific Islands.

Compliance Monitoring with DURAG

As an exclusive distributor for DURAG complete Continuous Emissions Monitoring Systems, AquaGas Pty Ltd offers comprehensive and innovative solutions for gas, dust, and flow monitoring.

DURAG is a leading manufacturer of high-quality and reliable emissions monitoring equipment, and AquaGas Pty Ltd is proud to offer their range of products to customers across various industries. With a focus on accuracy, durability, and compliance, DURAG’s CEMS solutions are designed to meet the most demanding requirements for emissions monitoring.

AquaGas Pty Ltd.’s partnership with DURAG ensures that customers receive top-of-the-line products and excellent technical support to help them achieve their emissions reduction goals.

SMARTCEMS cost effective solutions

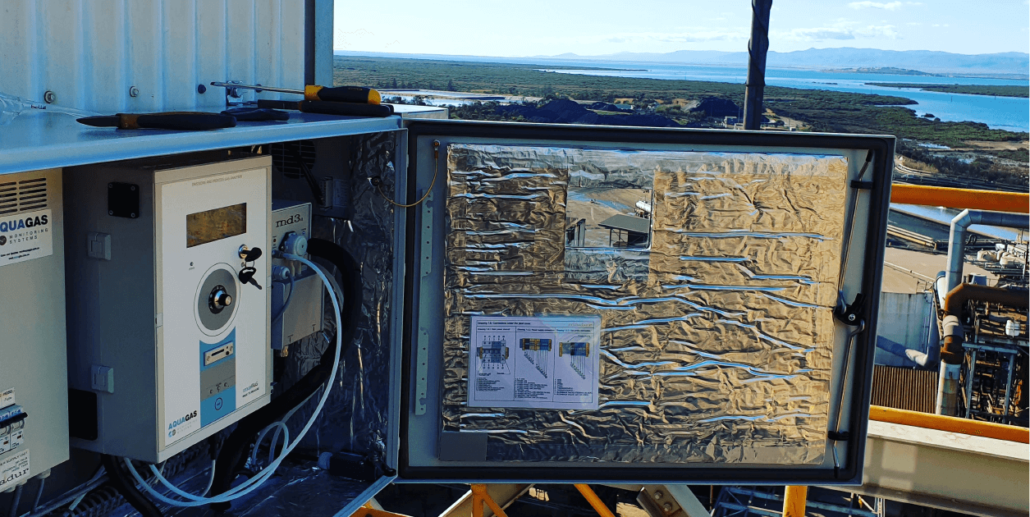

AquaGas Pty Ltd offers a cost-effective and advanced solution for emissions monitoring with its SmartCEMS multigas analyser.

The SmartCEMS analyser is designed to measure multiple pollutants such as CO, CO2, NOx, SO2, and NMHC, and is equipped with advanced sensors and software for accurate and reliable readings. The analyser is also capable of self-calibration and remote monitoring, which reduces maintenance costs and ensures consistent data quality.

AquaGas Pty Ltd.’s SmartCEMS analyser is an excellent option for businesses and industries seeking to comply with environmental regulations while also reducing costs associated with monitoring emissions.

With the SmartCEMS analyser, customers can effectively manage their emissions while also improving their bottom line.

Combustion

SETNAG Oxygen analyser is an advanced and reliable solution for oxygen monitoring in Continuous Emissions Monitoring Systems (CEMS) applications. The analyser is designed to provide accurate and precise measurements of oxygen concentrations in a variety of gases, including flue gas and ambient air. The SETNAG Oxygen analyser uses advanced technology and a robust construction to provide long-term stability and resistance to chemical and thermal stresses, ensuring reliable and accurate measurements over extended periods.

With its advanced features, the SETNAG Oxygen analyser is an ideal choice for businesses seeking to comply with environmental regulations and monitor their emissions accurately and reliably. Overall, the SETNAG Oxygen analyser is an essential tool for any CEMS application that requires insitu or extractive precise oxygen measurements to ensure compliance and improve process efficiency.

References

AquaGas is supporting the global industrial community with high performance environmental and process monitoring systems (Continuous Emissions Monitoring Systems, Air Quality Monitoring Systems, Online process analysers, Water Quality Monitoring Systems and tunnel sensors) specifically designed and built to meet your application requirements.

AT THE HEART OF INNOVATION

Ellona has more than 200 man years of experience in sensors and particularly in gas sensors, VOC and odors, developing electronic nose and nuisances data banks associating miniaturized sensors arrays with AI. Ellona provides environmental intelligence solutions based devices for outdoor and indoor spaces. These solutions help decision makers improve their environments using sensors, capable of analyzing and monitoring both air quality and nuisances (gas, odours, particles, lights, sounds, …).