Committed to a better environment and a sustainable future, AquaGas Pty Ltd is delighted to announce its new partnership with one of the leading manufacturer of water quality sensors and monitoring solutions. AquaGas Pty Ltd has recently been appointed by HORIBA as exclusive sales and technical representative for the extensive range of industrial water quality sensors and online analysers.

HORIBA manufactures and sells automotive emission measurement systems, environmental measuring instruments, wide range of scientific analyzers, and medical diagnostic analyzers, and measuring equipment used in the semiconductor industry. HORIBA also manufactures and markets peripheral measuring and analysis devices. Moreover, the Company equips such facilities as laboratories with measuring and analytical equipment for R&D, production, and other applications.

The integration of HORIBA Process and Environmental product range enables AquaGas to respond, with a broad selection of field sensors (H-1® and SLIM 48/96® Series) for the automation of industrial processes, to the growing demand for smart and cost effective monitoring solutions within the water treatment industry. HORIBA wet chemistry and optical (UV and IR) based instruments allow efficient and homogeneous system integration for environmental monitoring and industrial process automations with the choice of 25+ models covering essential water quality parameters such as pH, dissolved oxygen, oxidation-reduction potential, fluoride ion, electrical conductivity, electrical resistance, MLSS, turbidity, free residual chlorine, COD, TP, TN, Oil film and Oil contamination and more.

pH, dissolved oxygen, oxidation-reduction potential, fluoride ion, electrical conductivity,

H-1® and SLIM 48/96® Series comprehensive range of Water Quality Sensors suited to all kinds of water treatment from purified water to wastewater.

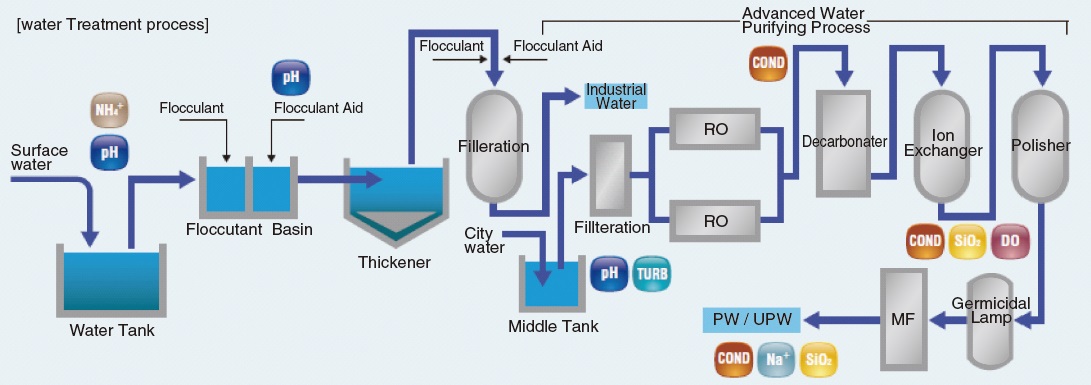

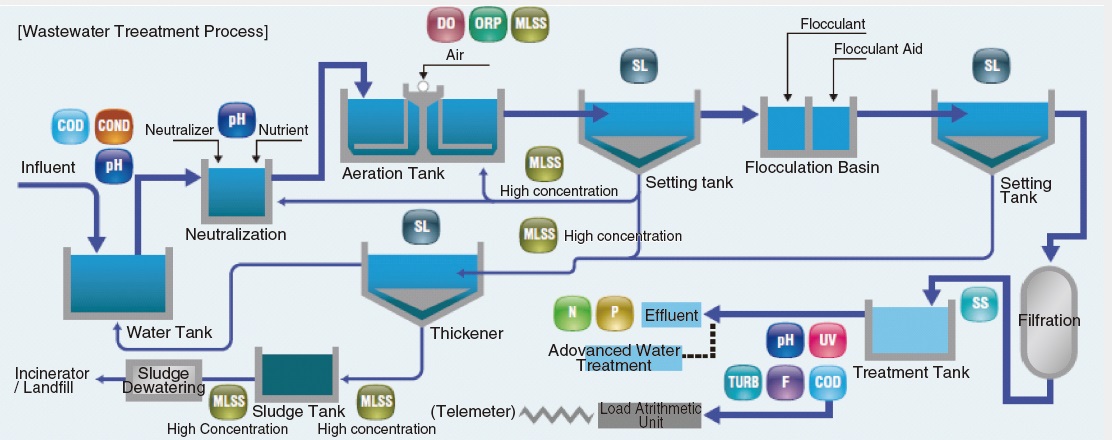

WTP water treatment plant

Wastewater treatment plant

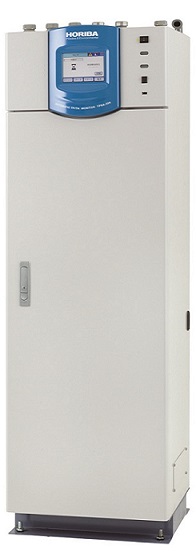

CODA-500®: High-performance Automatic COD Analyser. Tailored to the needs of environmental authorities and plant operators the CODA-500® is designed for the automation of industrial processes.

Advances technologies based on 30 years of accumulated expertise, HORIBA.

Total Nitrogen/Phosphorus

TPNA-500®, a state-of-the-art Total Nitrogen/Phosphorus Analyser adopting 60 years of water measurement technology

Everything from precise measurement to reduced running costs. HORIBA leading the world in practical environmental analysis technology will give a benefit for Total Nitrogen/Phosphorus monitoring.

HORIBA TW-100® Drinking Water Analyser is a process

water quality monitoring system designed for drinking water and water distribution plants. The

TW-100® Drinking Water Analyser uses a reagent free method for online monitoring of

turbidity, color, free chlorine and pressure resulting in a significant reduction of the ownership costs.

TW-100® Drinking Water Analyser is a field proven device that requires minimal maintenance and improves process control.

Organic Pollutant Analyser

OPSA-150® is a new Organic Compounds and Persistent Organic Pollutant Analyser that uses HORIBA’s proprietary Rotary Cell Length Modulation, a measuring technique incorporating 25 years of expertise. The OPSA can be used as an organic pollutant monitor at drainage systems for determining compliance with COD monitoring regulations, for monitoring quality of water measuring levels of organic matter at water supply intakes, and as an organic monitor on process lines (phenol meter).

*Pole mount, outdoor cover, and analysis panel are available as options.

More…

LO-300® Laser scanning Oil Film Detector is a laser based Oil Pollution Analyser designed for on-line detection of oil leakage.

LO-300® Laser scanning Oil Film Detector, scans water surface with its built in laser to detect the presence of oil films on water surfaces and groundwaters. TheLO-300® detects floating oil by sensing the difference in the intensity of reflection between water and oil. As compared with spotlight-based systems, the LO-300® adopted laser scanning method prevents interferences from water surface level fluctuation, and changes in distance between the water surface and the detector.

More…

Greenhouse Gases (GHG) Fugitive Emissions

/in Continuous Emissions Monitoring Systems, Emissions Analyser, Emissions monitoring, Process Monitoring, Water Quality /by AquaGasGHG Monitoring

The principal supplier of water, wastewater & drainage servicing to over 2 million people throughout Australia, awarded AquaGas Pty Ltd for the supply of 2 SmartCEMS GHG for their wastewater treatment facilities.

Broadly, wastewater systems contribute to GHG emissions not only through their significant consumption of grid electricity in most cases, but also through direct emissions of nitrous oxide (N2O) and methane (CH4). These are often called ‘fugitive’ gases because they escape from the collection and treatment systems.

For this project AquaGas scope includes the provision, installation, and commissioning of 2 stand alone monitoring systems designed to monitor continuously and simultaneously N2O, CH4, CO2 and O2. Equipped with multistream sampling system, these analysers are used to check multiple sources across a wide range of locations in the client’s production facilities.

AquaGas online analysers are suited to a large range of applications related to Greenhouse Gas fugitive emissions such as emissions and process monitoring at

When used to their full extent, the expanded capabilities offered by accurate and reliable analysers can bring real benefits by providing fast access to detailed GHG emissions data and an accurate real time overview of operating conditions at urban utilities and industrial sites.

More on SmartCEMS® GHG

AquaGas is supporting the global industrial community with high performance environmental and process monitoring systems (Continuous Emissions Monitoring Systems, Air Quality Monitoring Systems, Online process analysers, Water Quality Monitoring Systems and tunnel sensors) specifically designed and built to meet your application requirements.

Continuous Emissions Monitoring Systems

Process gas online monitoring

Indoor and Ambient Air

Water Quality Monitoring Systems

SmartCEMS® GH2 deployed @ multiple GH2 facilities across Australia

/in Air Quality, Emissions Analyser, Emissions monitoring, Process Monitoring /by AquaGasThe green hydrogen revolution begins with measurement

AquaGas Pty Ltd is proud to announce that one of Australia’s leaders in the renewable energy and low-carbon fuels awarded AquaGas Pty Ltd for the supply of six (6) SmartCEMS® GH2 for their green hydrogen production facilities.

Our client is taking a global leadership position in the renewable energy and green products industry by harnessing the world’s renewable energy resources to produce renewable electricity, green hydrogen, and other green industrial products such as green ammonia and green iron.

For this project AquaGas scope includes the provision, installation, and commissioning of 6 stand alone monitoring systems designed to monitor continuously and simultaneously H2 and O2 across a wide range of locations in their production facilities.

The SmartCEMS® GH2 sensor technology provides real-time continuous and simultaneous monitoring of H2 and O2 into GH2 gas streams. With fast response times and no cross-sensitivity to any other gases in the stream, including CO and H2S, the SmartCEMS® GH2 does not require reference or carrier gas systems.

The SmartCEMS® GH2 combines Thermal Conductivity Detection, Electrochemical and Paramagnetic technologies in the same analyser resulting in unique measurement possibilities including complex gas sensors configurations with a large selection of dynamic measuring range (ppm to %).

More on AquaGas Monitoring Systems for GH2

AquaGas is supporting the global industrial community with high performance environmental and process monitoring systems (Continuous Emissions Monitoring Systems, Air Quality Monitoring Systems, Online process analysers, Water Quality Monitoring Systems and tunnel sensors) specifically designed and built to meet your application requirements.

Continuous Emissions Monitoring Systems

Process gas online monitoring

Indoor and Ambient Air

Water Quality Monitoring Systems

SmartCEMS® GHG

/in Air Quality, CEMS, gas detection, New products, Process Monitoring /by AquaGasGHG emissions from wastewater handling

Broadly, wastewater systems contribute to Greenhouses gases (GHG) emissions not only through their significant consumption of grid electricity in most cases, but also through direct emissions of nitrous oxide (N2O) and methane (CH4). These are often called ‘fugitive’ gases because they escape from the collection and treatment systems.

CH4 emission: Wastewater contains organics, which can be biologically converted to CH4 in the absence of oxygen (i.e., under anaerobic conditions). In some parts of wastewater collection and treatment systems, anaerobic conditions prevail, leading to the formation of CH4 and its subsequent emission into the atmosphere.

N2O emission: Wastewater contains nitrogen, which needs to be removed to avoid nutrient enrichment of receiving waters. Biological nitrogen removal has been implemented at most large wastewater treatment plants in Australia. N2O is either an intermediate reaction or a by-product of the key biological reactions involved. Therefore, N2O is formed in, and could be emitted from, wastewater treatment plants.

The indirect emissions are expected to decrease substantially in the coming decade, due to both the increased recovery of energy from wastewater (biogas from anaerobic digestion) and improved efficiency of electrical energy use for wastewater treatment.

Furthermore, the current trend is towards increasing renewable energy supply, with resultant lower emission factors. Therefore, it is foreseeable that direct emissions might in future dominate the GHG profile of many wastewater treatment plants. Indeed, for some treatment plant in Australia, this may already be true.

Actual methane and nitrous oxide emissions associated with wastewater handling vary significantly, depending on the type of system and a range of operating factors.

Emissions can make up a substantial portion of direct GHG emissions reported as part of the total for water utilities that serve urban areas. The existing GHG reporting (NGER) system in Australia does not make provision for measurements or estimates of actual direct emissions of nitrous oxide and methane emissions from wastewater handling.

Understanding of greenhouse gas emissions related to wastewater handling has improved a lot in the last ten years, thanks to the efforts of researchers and the water industry, including significant contributions from Australia.

Committed to a better environment, AquaGas Pty Ltd is proud to supply and support a broad product range featuring a line of analysers tailored to the measurement of Greenhouse Gases emissions in the environment or directly at the source. Already selected by councils and water agencies, AquaGas analysers offer exclusive features implemented to fulfil the needs of today’s urban utilities and waste recycling facilities.

AquaGas online analysers are suited to a large range of applications related to Greenhouse Gas fugitive emissions such as emissions and process monitoring at

When used to their full extent, the expanded capabilities offered by accurate and reliable analysers can bring real benefits by providing fast access to detailed GHG emissions data and an accurate real time overview of operating conditions at urban utilities and industrial sites.

SmartCEMS® GHG

Having the N2O nitrous oxide, CH4 methane, and CO2 carbon dioxide measurements available in real time ensures greater predictivity and broader scope of fugitive emissions, allowing process problems to be resolved before they escalate.

The SmartCEMS® GHG sensor technology provides real-time continuous and simultaneous monitoring of CH4, CO2, N2O and O2 at wastewater plants, waste recycling facilities, landfill (…). With fast response times and no cross-sensitivity to any other gases in the stream, including CO and H2S, the SmartCEMS GHG does not require reference or carrier gas systems.

The SmartCEMS® GHG combines Non-Directive Infrared, Electrochemical, Photoionization and Paramagnetic technologies in the same analyser resulting in unique measurement possibilities including complex gas sensors configurations with a large selection of dynamic measuring range (ppm to %).

The Smart CEMS® offers multiple configurationsof sensors and methods suited to the fugitive emissions at industrial sites and urban utilities. Here are the measuring parameters for the most common gases. For other gases or different measuring ranges (MR), please consult us.

Available in single or multistream configuration, the SmartCEMS GHG® associated gas sampling and conditioning system features a multistage particulate filtration system, a powerful dew point stabilizer (Peltier, Nafion or dual outputs), a variable speed sampling pump and continuous removal of sample condensates.

In addition to its exclusive analytical capabilities, the SmartCEMS concept offers an ease of use for operation and maintenance tasks. All system components are field replaceable including the measuring cells delivered pre-calibrated to site. The SmartCEMS GHG® offers enhanced simplicity, making it easier for operators at any level of experience to access or relay key operational and maintenance-related data. This concept prevents unnecessary downtime and minimizing the risk of potential damage to key process plant or impaired hydrogen quality.

The inclusion of features such as remote connectivity allows the fast collection of diagnostics information, with engineers able to perform actions such as fault tracing or changes to an instrument’s configuration without having to be physically present.

IEC conformity

AquaGas analysers for the greenhouse gases monitoring complies in all aspect with the IEC60079-2 standards. AquaGas online analysers for GHG emissions monitoring are available in Purged and Pressurised (P&P) enclosure or IECEx certified version.

AquaGas is supporting the global industrial community with high performance environmental and process monitoring systems (Continuous Emissions Monitoring Systems, Air Quality Monitoring Systems, Online process analysers, Water Quality Monitoring Systems and tunnel sensors) specifically designed and built to meet your application requirements.

Continuous Emissions Monitoring Systems

Process gas online monitoring

Indoor and Ambient Air

Water Quality Monitoring Systems

A note of thanks

/in Air Quality /by AquaGasWe started AquaGas 10 years ago with a view to bringing the latest and best environmental monitoring technologies to Australia; designed, integrated, and configured to your specific requirements at the best possible prices. Our business would be nothing without you, our customers, so we thank you sincerely for your support:

We take great pride in our customer service – if you could please take a minute to leave an honest review for us on Google of your experience business with us, it would be much appreciated.

Follow Us On

AquaGas is supporting the global industrial community with high performance environmental and process monitoring systems (Continuous Emissions Monitoring Systems, Air Quality Monitoring Systems, Online process analysers, Water Quality Monitoring Systems and tunnel sensors) specifically designed and built to meet your application requirements.

Continuous Emissions Monitoring Systems

Process gas online monitoring

Indoor and Ambient Air

Water Quality Monitoring Systems

Warmth, joy, and peace from our crew to yours!

/in Air Quality /by AquaGasTo our clients, partners, and colleagues:

As we begin the new year, it is a perfect time to remind you how much we appreciate your business. You inspire us as we work together to create a healthier planet, a better environment, and a sustainable future, one project at a time. It has been a pleasure and a privilege to work with you over the past year, and we look forward to taking up challenges with you again this year.

Hoping your Christmas and Holiday season was blessed by the love of family, the warmth of home and the company of good friends.

Happy New Year from AquaGas Pty Ltd!

AquaGas is supporting the global industrial community with high performance environmental and process monitoring systems (Continuous Emissions Monitoring Systems, Air Quality Monitoring Systems, Online process analysers, Water Quality Monitoring Systems and tunnel sensors) specifically designed and built to meet your application requirements.

Continuous Emissions Monitoring Systems

Process gas online monitoring

Indoor and Ambient Air

Water Quality Monitoring Systems

PROCEAS® in GH2 Plants

/in Air Quality, AP2e, Continuous Emissions Monitoring Systems, Emissions Analyser, Emissions monitoring, gas detection, Indoor air quality, Process Monitoring /by AquaGasProcess Control and Purity in GH2 Plants

The realization of the importance of shifting from fossil fuels, both for environmental and energy security reasons, makes the use of green hydrogen extremely pertinent, as one of several potential low-carbon fuels that could take the place of fossil hydrocarbons in GH2 Plants.

To maintain safe operation, optimise the power to hydrogen conversion, and maximize the quality and purity of the produced hydrogen; the green hydrogen production process relies on measuring multiple parameters as extensively as possible and using the resulting data to inform GH2 Plants Operators.

AquaGas online analysers are suited to a large range of applications within the GH2 Plants providing real time gas stream composition at key locations:

When used to their full extent, the expanded capabilities offered by accurate and reliable analysers can bring real benefits by optimising efficiency and safety, and providing fast access to detailed data and an accurate real time overview of the operating conditions.

Committed to a better environment, AquaGas Pty Ltd is proud to supply and support a broad product range featuring a line of analysers and gas detection systems tailored to the GH2 industry. Already selected by several of the main actors in the green hydrogen industry, AquaGas analysers offer exclusive features implemented to fullfil the needs of today’s Green Hydrogen production.

The ProCeas® multigas analyser for GH2 applications

For process control and purity assessment at GH2 Plants, the ProCeas® uses the patented OFCEAS technology, based on extractive absorption spectroscopy. This laser-based technology is able to measure gases down to sub-ppb levels of concentration, with an unforeseen quality of measurement in terms of accuracy and repeatability. The ProCeas® samples the gas at low pressure, with an internal pressure below 100 mbar absolute. This dilution reduces the volume needed to get a correct measurement and optimizes the response time of the analyser. In the end the system requires small samples of hydrogen.

Additionally, ProCeas® has an integrated auto calibration of the measurement system, allowing no drift under normal use of the instrument. ProCeas® can analyse a large range of impurities with limited service and maintenance costs.

The ProCeas® Hydrogen key features include:

The field of application for fast and precise online analysers in the GH2 Plants is considerably exhaustive. Here below are two cases where online measurement of H2 and O2 is critical.

The ProCeas® H2 trace gas analyser

Ensure safe Electrolyse with the ProCeas® H2

At their simplest level, electrolysers produce oxygen at the anode and hydrogen at the cathode. However, many reactions in the electrolyser can cause small concentrations of oxygen to build up in the hydrogen stream and hydrogen to build up in the oxygen. This is a fault condition and must be detected by appropriate instruments that can be used as part of an automated safety system that can initiate actions in the event of an oxy-fuel gas mixing alarm being activated.

With a detection limit down to 3ppm for the H2 and 1ppm for the O2, The ProCeas® hydrogen is perfectly suited to O2 and H2 trace gas monitoring and consequently can be used to measure both traces of hydrogen in the oxygen stream and traces of oxygen in the hydrogen stream.

The ProCeas® H2 Purity

Keeping production up to standard with the ProCeas® H2 Purity

As a multi-stage process, green hydrogen production requires accurate measurement of a variety of parameters to ensure safe and efficient operation. ISO14687-2 stipulates the impurities that need to be measured and their respective limits throughout the various stages of the production process to help maintain control and avoid potential issues that could affect efficiency or safety.

ProCeas® hydrogen purity is a complete pre-calibrated multicomponent (H2S, CO, CO2, CH4, H2O, O2, NH3, H2O, HCHO, etc.) laser infrared spectrometer for measurements of impurities in hydrogen gas streams.

(ppm)

(ppm)

IEC conformity

AquaGas analysers for the GH2 industry complies in all aspects with the IEC60079-2 standards. AquaGas online analysers for the GH2 industry are available in Purged and Pressurised (P&P) enclosure or IECEx certified version.

AquaGas is supporting the global industrial community with high performance environmental and process monitoring systems (Continuous Emissions Monitoring Systems, Air Quality Monitoring Systems, Online process analysers, Water Quality Monitoring Systems and tunnel sensors) specifically designed and built to meet your application requirements.

Continuous Emissions Monitoring Systems

Process gas online monitoring

Indoor and Ambient Air

Water Quality Monitoring Systems

SmartCEMS® in GH2 Plants

/in Air Quality, CEMS, Continuous Emissions Monitoring Systems, Emissions Analyser, Emissions monitoring, Process Monitoring /by AquaGasProcess Control and Purity in GH2 Plants

The realization of the importance of shifting from fossil fuels, both for environmental and energy security reasons, makes the use of green hydrogen extremely pertinent, as one of several potential low-carbon fuels that could take the place of fossil hydrocarbons.

To maintain safe operation, optimise the power to hydrogen conversion, and maximize the quality and purity of the produced hydrogen; the green hydrogen production process relies on measuring multiple parameters as extensively as possible and using the resulting data to inform Plant Operators.

AquaGas online analysers are suited to a large range of applications within the GH2 industry providing real time gas stream composition at key locations:

When used to their full extent, the expanded capabilities offered by accurate and reliable analysers can bring real benefits by, optimising efficiency and safety, and providing fast access to detailed data and an accurate real time overview of the operating conditions.

SmartCEMS® GH2

Committed to a better environment, AquaGas Pty Ltd is proud to supply and support a broad product range featuring a line of analysers and gas detection systems tailored to the GH2 industry. Already selected by several of the main actors in the green hydrogen industry, AquaGas analysers offer exclusive features implemented to full fil the needs of today’s Green Hydrogen production.

Keeping an eye on gas quality with the SmartCEMS® GH2.

Having the hydrogen and oxygen measurements available in real time ensures greater predictivity also facilitates proactive maintenance, allowing process problems to be resolved before they escalate.

The SmartCEMS® GH2 sensor technology provides real-time continuous and simultaneous monitoring of H2 and O2 into GH2 gas streams. With fast response times and no cross-sensitivity to any other gases in the stream, including CO and H2S, the SmartCEMS GH2 does not require reference or carrier gas systems.

The SmartCEMS® GH2 combines Thermal Conductivity Detection, Electrochemical and Paramagnetic technologies in the same analyser resulting in unique measurement possibilities including complex gas sensors configurations with a large selection of dynamic measuring range (ppm to %).

The Smart CEMS® offers multiple sensor and method configurations suited to the GH2 industry. Here are the measuring parameters for the most common gases. For other gases or different measuring ranges (MR), please consult us.

Available in single or multistream configuration, the SmartCEMS GH2® associated gas sampling and conditioning system features a multistage particulate filtration system, a powerful dew point stabilizer (Peltier, Nafion or dual outputs), a variable speed sampling pump and continuous removal of sample condensates.

In addition to its exclusive analytical capabilities, the SmartCEMS concept offers an ease of use for operation and maintenance tasks. All system components are field replaceable including the measuring cells delivered pre-calibrated to site. The SmartCEMS GH2® offers enhanced simplicity, making it easier for operators at any level of experience to access or relay key operational and maintenance-related data. This concept prevents unnecessary downtime and minimizing the risk of potential damage to key process plant or impaired hydrogen quality.

The inclusion of features such as remote connectivity allows the fast collection of diagnostics information, with engineers able to perform actions such as fault tracing or changes to an instrument’s configuration without having to be physically present.

IEC conformity

AquaGas analysers for the GH2 industry complies in all aspects with the IEC60079-2 standards. AquaGas online analysers for the GH2 industry are available in Purged and Pressurised (P&P) enclosure or IECEx certified version.

AquaGas is supporting the global industrial community with high performance environmental and process monitoring systems (Continuous Emissions Monitoring Systems, Air Quality Monitoring Systems, Online process analysers, Water Quality Monitoring Systems and tunnel sensors) specifically designed and built to meet your application requirements.

Continuous Emissions Monitoring Systems

Process gas online monitoring

Indoor and Ambient Air

Water Quality Monitoring Systems

GREEN HYDROGEN [GH2]

/in Air Quality, AP2e, Emissions Analyser, gas detection, Indoor air quality, low pressure sampling LPS, Multipoint Monitoring, on-board analysers /by AquaGasGreen hydrogen (GH2) is hydrogen that is generated by renewable energy or from low-carbon power. One of the paths to near-total decarbonization is supplying the whole energy system using clean renewable power combined with low-carbon fuels. Hydrogen is an important component of global efforts around the world to de-carbonise the energy sector.

The realization of the importance of shifting from fossil fuels, both for environmental and energy security reasons, makes the use of green hydrogen extremely pertinent, as one of several potential low-carbon fuels that could take the place of fossil hydrocarbons.

The affordability of renewable energy resources as well as the developments in electrolysis technology increase the potential of “green hydrogen” as a clean and sustainable form of fuel production. The global hydrogen production is set to more than double in the decade between 2020 and 2030, from 70 million tons to 170 tons. Projections beyond 2030 point to a further increase as production technologies become more efficient and production costs fall.

GH2 is a versatile form of energy

Green hydrogen produced by the electrolysis of water may be used to decarbonize sectors which are hard to power from any energy other than fossil fuels, such as steel and cement production, and thus help to limit climate change.

Green hydrogen can be blended into existing natural gas pipelines, and used to produce green ammonia, the main constituent of fertilizer production. Green hydrogen can transform into many different types of energy, including electric and synthetic gas for heating, powering electronics, fuelling vehicles. Right now, the most common uses of green hydrogen energy are oil refining, steel manufacturing, ammonia production and food processing.

Hydrogen is abundant, it’s easier to store and provides a better efficiency than other energy sources.

Producing GH2

Key to the production of green hydrogen is the use of an electrolyser to split water into hydrogen and oxygen while renewable sources such as wind, solar or hydroelectric power generate the necessary power for the electrolysis process. Carrying out large scale electrolysis as needed to provide the quantities of hydrogen to overcome the growing energy demand presents several challenges.

It is obviously imperative that the entire production chain is monitored continuously for process control and safety. That includes maintaining optimal electrolyser performance, as well as avoiding potentially explosive leaks. Hydrogen affects the BTU value of the natural gas, therefore measuring the amount of hydrogen present in natural gas is critical for utility companies, industrials, pipeline distribution network, and of course the end user.

GH2 process monitoring and control

Plant performance, energy consumption, production rates, purity and storage are among the key performance indicators (KPI) for hydrogen production which require visibility to ensure efficient production.

To maintain safe operation, optimise the power to hydrogen conversion, and maximize the quality and purity of the produced hydrogen; the green hydrogen production process relies on measuring multiple parameters as extensively as possible and using the resulting data to inform Plant Operators.

Today’s online measurement technologies provide greater accuracy, range and depth of information that can be used to assess both process performance and the status of the plant, especially important in preventing unexpected problems such as faults or failures in safety-critical applications.

AquaGas commitment

The green hydrogen revolution begins with measurement

Committed to a better environment, AquaGas Pty Ltd is proud to supply and support a broad product range featuring a line of analysers and gas detection systems tailored to the GH2 industry. Already selected by several of the main actors in the green hydrogen industry, AquaGas analysers offer exclusive features implemented to full fil the needs of today’s Green Hydrogen production.

As a way of optimizing process performance, AquaGas online analysers are already playing a role in exploring the potential of green hydrogen as a plentiful and sustainable energy source.

AquaGas monitoring solutions provide meaningful real time information, improve overall hydrogen usage to reduce costs and ensure process optimization. Knowing GH2 composition in real time allows operators to make continuous adjustments that optimize hydrogen production and usage while ensuring safe operations.

Field of Applications

AquaGas online analysers are suited to a large range of applications within the GH2 industry providing real time gas stream composition at key locations:

When used to their full extent, the expanded capabilities offered by accurate and reliable analysers can bring real benefits by optimising efficiency and safety, and providing fast access to detailed data and an accurate real time overview of the operating conditions.

As in any industrial processes, gauging performance and identifying potential areas for improvements in the green hydrogen production process relies on accurate monitoring and plant feedback.

The field of application for fast and precise online analysers in the GH2 industry is considerably exhaustive. Here below are three cases where online measurement of H2 and O2 is critical.

AquaGas Monitoring Solutions for the GH2 Industry

Keeping an eye on gas quality

Having the hydrogen and oxygen measurements available in real time ensures greater predictability and also facilitates proactive maintenance, allowing process problems to be resolved before they escalate.

The SmartCEMS GH2 is a powerful and reliable process analyser for GH2 plants. It features the integration of TCD and Paramagnetic cells for online measurement of H2 and O2 across 0-100% range with a precision of 0.01%. The SmartCEMS is a cost-effective and versatile monitoring system for process control. Polyvalent and modular, its associated sampling system has a large selection of options and configurations to cover an extensive range of application criteria.

Ensure safe Electrolyse

At their simplest level, electrolysers produce oxygen at the anode and hydrogen at the cathode. However, many reactions in the electrolyser can cause small concentrations of oxygen to build up in the hydrogen stream and hydrogen to build up in the oxygen. This is a fault condition and must be detected by appropriate instruments that can be used as part of an automated safety system that can initiate actions in the event of an oxy-fuel gas mixing alarm being activated.

The ProCeas® H2 is a multigas spectrometer designed for trace gases monitoring in GH2 and H2 gas streams. With a detection limit down to 3ppm for the H2 and 1ppm for the O2, The ProCeas® hydrogen is perfectly suited to O2 and H2 traces monitoring and consequently can be used to measure both traces of hydrogen in the oxygen stream and traces of oxygen in the hydrogen stream.

Keeping production up to standard with the ProCeas

As a multi-stage process, green hydrogen production requires accurate measurement of a variety of parameters to ensure safe and efficient operations. ISO14687-2 stipulates the impurities that need to be measured and their respective limits throughout the various stages of the production process to help maintain control and avoid potential issues that could affect efficiency or safety.

ProCeas® hydrogen purity is a complete pre-calibrated multicomponent (H2S, CO, CO2, CH4, H2O, O2, NH3, H2O, HCHO, etc.) laser infrared spectrometer for measurements of impurities in hydrogen gas streams. ProCeas® hydrogen purity empowers trouble-free compliance to ISO14687-2.

IEC conformity

AquaGas analysers for the GH2 industry complies in all aspects with the IEC60079-2 standards. AquaGas online analysers for the GH2 industry are available in Purged and Pressurised (P&P) enclosure or IECEx certified version.

AquaGas is supporting the global industrial community with high performance environmental and process monitoring systems (Continuous Emissions Monitoring Systems, Air Quality Monitoring Systems, Online process analysers, Water Quality Monitoring Systems and tunnel sensors) specifically designed and built to meet your application requirements.

Continuous Emissions Monitoring Systems

Process gas online monitoring

Indoor and Ambient Air

Water Quality Monitoring Systems

HORIBA Process and Environmental

/in Applications, hydrocarbons, Mine water, online monitoring, Portable instrument, Process Monitoring, suspended oil, waste-to-energy, wastewater, wastewater treatment plant, water discharge, Water Quality, water treatment plant, WQMS /by aymericCommitted to a better environment and a sustainable future, AquaGas Pty Ltd is delighted to announce its new partnership with one of the leading manufacturer of water quality sensors and monitoring solutions. AquaGas Pty Ltd has recently been appointed by HORIBA as exclusive sales and technical representative for the extensive range of industrial water quality sensors and online analysers.

HORIBA manufactures and sells automotive emission measurement systems, environmental measuring instruments, wide range of scientific analyzers, and medical diagnostic analyzers, and measuring equipment used in the semiconductor industry. HORIBA also manufactures and markets peripheral measuring and analysis devices. Moreover, the Company equips such facilities as laboratories with measuring and analytical equipment for R&D, production, and other applications.

The integration of HORIBA Process and Environmental product range enables AquaGas to respond, with a broad selection of field sensors (H-1® and SLIM 48/96® Series) for the automation of industrial processes, to the growing demand for smart and cost effective monitoring solutions within the water treatment industry. HORIBA wet chemistry and optical (UV and IR) based instruments allow efficient and homogeneous system integration for environmental monitoring and industrial process automations with the choice of 25+ models covering essential water quality parameters such as pH, dissolved oxygen, oxidation-reduction potential, fluoride ion, electrical conductivity, electrical resistance, MLSS, turbidity, free residual chlorine, COD, TP, TN, Oil film and Oil contamination and more.

pH, dissolved oxygen, oxidation-reduction potential, fluoride ion, electrical conductivity,

H-1® and SLIM 48/96® Series comprehensive range of Water Quality Sensors suited to all kinds of water treatment from purified water to wastewater.

WTP water treatment plant

Wastewater treatment plant

Chemical Oxygen Demand

CODA-500®: High-performance Automatic COD Analyser. Tailored to the needs of environmental authorities and plant operators the CODA-500® is designed for the automation of industrial processes.

Advances technologies based on 30 years of accumulated expertise, HORIBA.

Total Nitrogen/Phosphorus

TPNA-500®, a state-of-the-art Total Nitrogen/Phosphorus Analyser adopting 60 years of water measurement technology

Everything from precise measurement to reduced running costs. HORIBA leading the world in practical environmental analysis technology will give a benefit for Total Nitrogen/Phosphorus monitoring.

Drinking Water Analyser

Organic Pollutant Analyser

*Pole mount, outdoor cover, and analysis panel are available as options.

More…

Oil Pollution

LO-300® Laser scanning Oil Film Detector is a laser based Oil Pollution Analyser designed for on-line detection of oil leakage.

LO-300® Laser scanning Oil Film Detector, scans water surface with its built in laser to detect the presence of oil films on water surfaces and groundwaters. TheLO-300® detects floating oil by sensing the difference in the intensity of reflection between water and oil. As compared with spotlight-based systems, the LO-300® adopted laser scanning method prevents interferences from water surface level fluctuation, and changes in distance between the water surface and the detector.

More…

AquaGas SmartCEMS® solution

/in Applications, Biogas, CEMS, Combustion control, Continuous Emissions Monitoring Systems, Direct Extractive, Emissions Analyser, Emissions monitoring, Emissions Testing, energy, environmental impact assessment and air quality control applications in urban and industrial areas, Gas coolers, landfill, Multipoint Monitoring, NDIR, New products, Power Station, Process Monitoring, Sampling system, stack emissions, VOC, waste incinerator, waste-to-energy /by aymericAquaGas is excited to increase its range of smart sensors with the release of a new branded CEMS (Continuous Emissions Monitoring System) recently acquired through an OEM with MADUR (Poland) and available across Oceania: the MAMOS.

The MAMOS SmartCEMS® is an online monitoring system designed by MADUR and integrated by AquaGas for the ANZ market which responds to industrials and environmental authorities today’s demand for a large range of industrial applications including small to large combustion plants (power station, paper mill, cement plant…), WTE (waste to Energy) installations as well as biogas, syngas and biomass generators.

Thanks to its modular and adaptive design the Mamos allows combining multiple sensors (PID, low and high range NDIR, Electrochemical, Thermal Conductivity) with applications specific sampling systems (Direct extractive heated and standard sampling train, Peltier cooler, Nafion membrane…). All system components are field replaceable and comes with a 24 months warranty.

Available as standalone unit, single analyser or redundant systems (fully backed up with manual and automatic redundancy) the Mamos SmartCEMS® is offered as a complete stationary CEMS for permanent installation or long term rental. AquaGas global service includes the various level of associated services (initial and final installation, commissioning, long term or punctual service agreement as well as the supply of consumables and critical spares for periods up to 5 years.

Moreover the MAMOS SmartCEMS® ensures minimal investment and extremely low ownership costs for trouble free environmental monitoring and process control operations while complying with Australians states regulations.

Here are some of the MAMOS SmartCEMS® main features: