GREEN HYDROGEN [GH2]

Green hydrogen (GH2) is hydrogen that is generated by renewable energy or from low-carbon power. One of the paths to near-total decarbonization is supplying the whole energy system using clean renewable power combined with low-carbon fuels. Hydrogen is an important component of global efforts around the world to de-carbonise the energy sector.

The realization of the importance of shifting from fossil fuels, both for environmental and energy security reasons, makes the use of green hydrogen extremely pertinent, as one of several potential low-carbon fuels that could take the place of fossil hydrocarbons.

The affordability of renewable energy resources as well as the developments in electrolysis technology increase the potential of “green hydrogen” as a clean and sustainable form of fuel production. The global hydrogen production is set to more than double in the decade between 2020 and 2030, from 70 million tons to 170 tons. Projections beyond 2030 point to a further increase as production technologies become more efficient and production costs fall.

GH2 is a versatile form of energy

Green hydrogen produced by the electrolysis of water may be used to decarbonize sectors which are hard to power from any energy other than fossil fuels, such as steel and cement production, and thus help to limit climate change.

Green hydrogen can be blended into existing natural gas pipelines, and used to produce green ammonia, the main constituent of fertilizer production. Green hydrogen can transform into many different types of energy, including electric and synthetic gas for heating, powering electronics, fuelling vehicles. Right now, the most common uses of green hydrogen energy are oil refining, steel manufacturing, ammonia production and food processing.

Hydrogen is abundant, it’s easier to store and provides a better efficiency than other energy sources.

Producing GH2

Key to the production of green hydrogen is the use of an electrolyser to split water into hydrogen and oxygen while renewable sources such as wind, solar or hydroelectric power generate the necessary power for the electrolysis process. Carrying out large scale electrolysis as needed to provide the quantities of hydrogen to overcome the growing energy demand presents several challenges.

It is obviously imperative that the entire production chain is monitored continuously for process control and safety. That includes maintaining optimal electrolyser performance, as well as avoiding potentially explosive leaks. Hydrogen affects the BTU value of the natural gas, therefore measuring the amount of hydrogen present in natural gas is critical for utility companies, industrials, pipeline distribution network, and of course the end user.

GH2 process monitoring and control

Plant performance, energy consumption, production rates, purity and storage are among the key performance indicators (KPI) for hydrogen production which require visibility to ensure efficient production.

To maintain safe operation, optimise the power to hydrogen conversion, and maximize the quality and purity of the produced hydrogen; the green hydrogen production process relies on measuring multiple parameters as extensively as possible and using the resulting data to inform Plant Operators.

Today’s online measurement technologies provide greater accuracy, range and depth of information that can be used to assess both process performance and the status of the plant, especially important in preventing unexpected problems such as faults or failures in safety-critical applications.

AquaGas commitment

The green hydrogen revolution begins with measurement

Committed to a better environment, AquaGas Pty Ltd is proud to supply and support a broad product range featuring a line of analysers and gas detection systems tailored to the GH2 industry. Already selected by several of the main actors in the green hydrogen industry, AquaGas analysers offer exclusive features implemented to full fil the needs of today’s Green Hydrogen production.

As a way of optimizing process performance, AquaGas online analysers are already playing a role in exploring the potential of green hydrogen as a plentiful and sustainable energy source.

AquaGas monitoring solutions provide meaningful real time information, improve overall hydrogen usage to reduce costs and ensure process optimization. Knowing GH2 composition in real time allows operators to make continuous adjustments that optimize hydrogen production and usage while ensuring safe operations.

Field of Applications

AquaGas online analysers are suited to a large range of applications within the GH2 industry providing real time gas stream composition at key locations:

- Upstream or downstream of the electrolyser

- At mixing stations or injection points

- Along the natural gas pipeline

- At customer sites just upstream of burners

When used to their full extent, the expanded capabilities offered by accurate and reliable analysers can bring real benefits by optimising efficiency and safety, and providing fast access to detailed data and an accurate real time overview of the operating conditions.

As in any industrial processes, gauging performance and identifying potential areas for improvements in the green hydrogen production process relies on accurate monitoring and plant feedback.

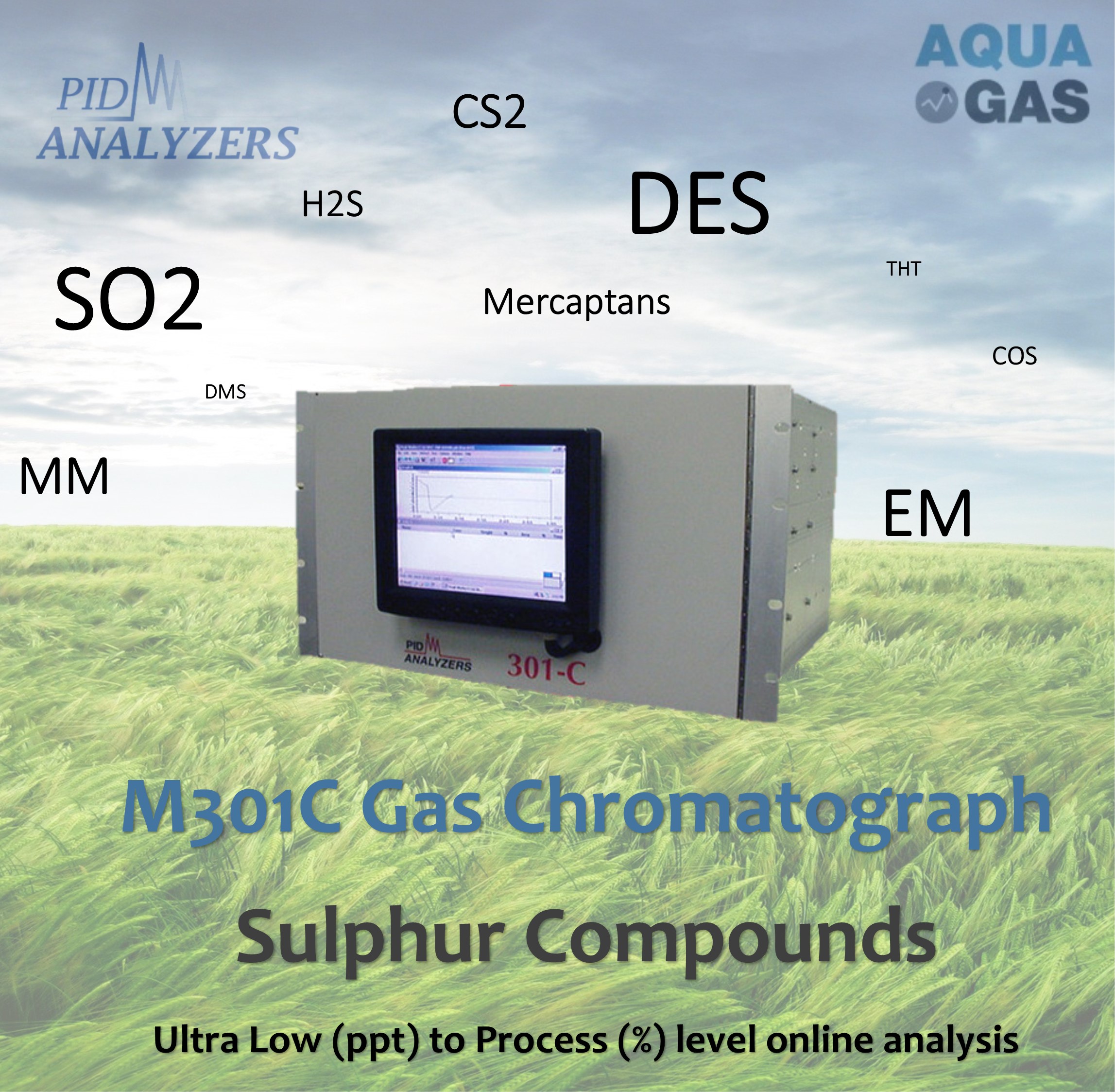

The field of application for fast and precise online analysers in the GH2 industry is considerably exhaustive. Here below are three cases where online measurement of H2 and O2 is critical.

AquaGas Monitoring Solutions for the GH2 Industry

Keeping an eye on gas quality

Having the hydrogen and oxygen measurements available in real time ensures greater predictability and also facilitates proactive maintenance, allowing process problems to be resolved before they escalate.

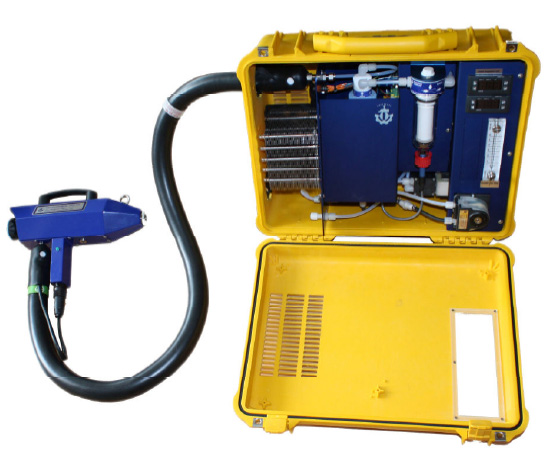

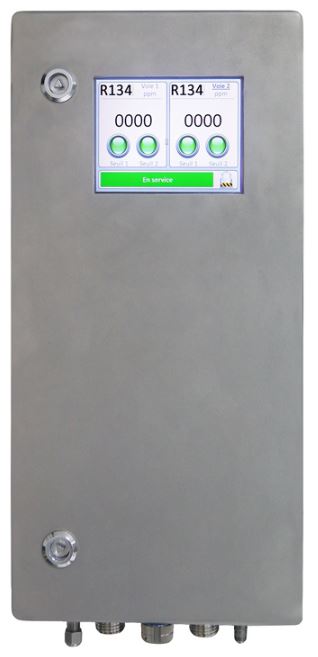

The SmartCEMS GH2 is a powerful and reliable process analyser for GH2 plants. It features the integration of TCD and Paramagnetic cells for online measurement of H2 and O2 across 0-100% range with a precision of 0.01%. The SmartCEMS is a cost-effective and versatile monitoring system for process control. Polyvalent and modular, its associated sampling system has a large selection of options and configurations to cover an extensive range of application criteria.

At their simplest level, electrolysers produce oxygen at the anode and hydrogen at the cathode. However, many reactions in the electrolyser can cause small concentrations of oxygen to build up in the hydrogen stream and hydrogen to build up in the oxygen. This is a fault condition and must be detected by appropriate instruments that can be used as part of an automated safety system that can initiate actions in the event of an oxy-fuel gas mixing alarm being activated.

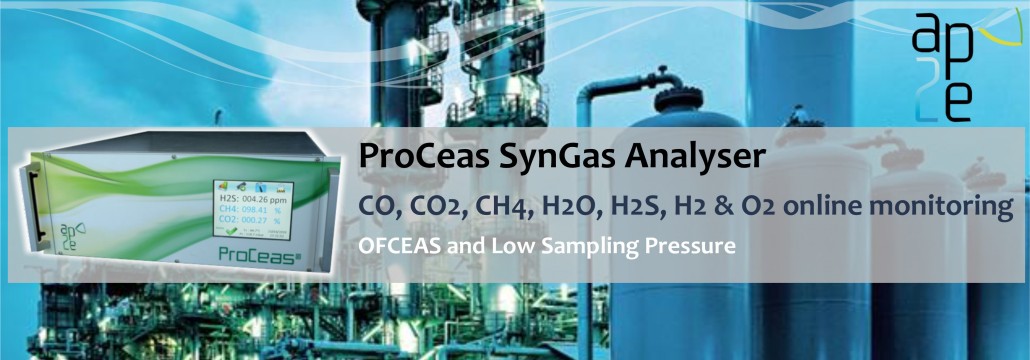

The ProCeas® H2 is a multigas spectrometer designed for trace gases monitoring in GH2 and H2 gas streams. With a detection limit down to 3ppm for the H2 and 1ppm for the O2, The ProCeas® hydrogen is perfectly suited to O2 and H2 traces monitoring and consequently can be used to measure both traces of hydrogen in the oxygen stream and traces of oxygen in the hydrogen stream.

As a multi-stage process, green hydrogen production requires accurate measurement of a variety of parameters to ensure safe and efficient operations. ISO14687-2 stipulates the impurities that need to be measured and their respective limits throughout the various stages of the production process to help maintain control and avoid potential issues that could affect efficiency or safety.

ProCeas® hydrogen purity is a complete pre-calibrated multicomponent (H2S, CO, CO2, CH4, H2O, O2, NH3, H2O, HCHO, etc.) laser infrared spectrometer for measurements of impurities in hydrogen gas streams. ProCeas® hydrogen purity empowers trouble-free compliance to ISO14687-2.

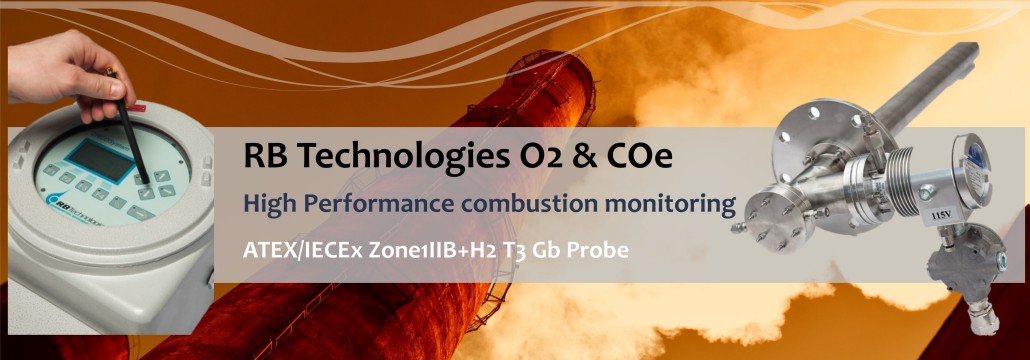

AquaGas analysers for the GH2 industry complies in all aspects with the IEC60079-2 standards. AquaGas online analysers for the GH2 industry are available in Purged and Pressurised (P&P) enclosure or IECEx certified version.

AquaGas is supporting the global industrial community with high performance environmental and process monitoring systems (Continuous Emissions Monitoring Systems, Air Quality Monitoring Systems, Online process analysers, Water Quality Monitoring Systems and tunnel sensors) specifically designed and built to meet your application requirements.