CEMS and Process Gas

Emissions and Process Instrumentation

Emissions and Process Instrumentation

Emissions and Process Instrumentation

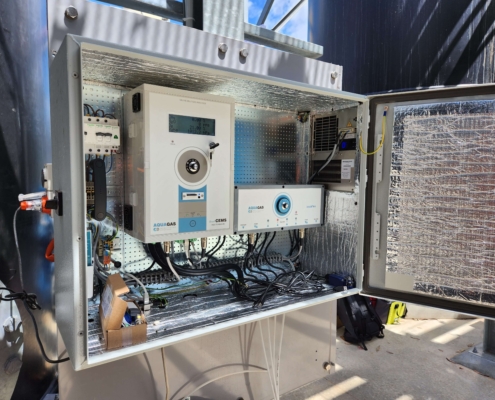

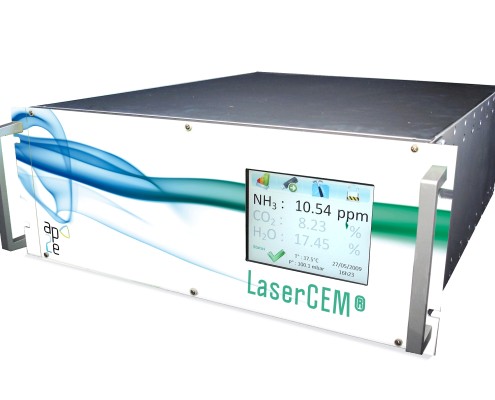

Governmental Authorities such as States Environmental Protection Agency’s and Australian Clean Air Regulations set stack emissions limits for pollutant concentrations at the point of release, and facility operating licences require emissions monitoring on a continuous basis. Continuous Emissions Monitoring Systems (CEMS) are operated 24/7 in harsh environments for regulatory purposes. AquaGas CEMS product range features robust and versatile sampling systems, analysers using dedicated technologies, and certified data acquisition and reporting systems necessary to comply with emissions standards. AquaGas Pty Ltd’s integrated systems and solutions are designed to achieve high reliability, long-term performance, and simplicity of use through operations and maintenance. The availability rate and accuracy of the consequent emissions data are two factors crucial to local authorities and plant operators.

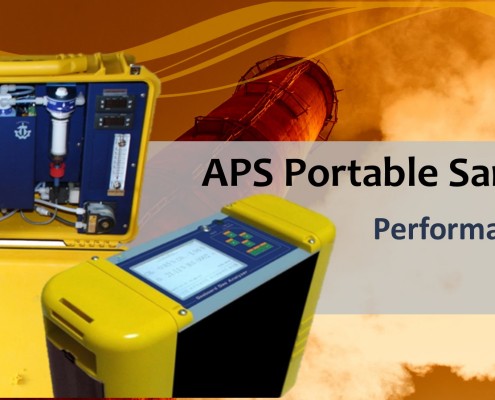

Emission and performance testing must be periodically performed on site by stack testers and mobile laboratories. AquaGas Portable Emission Measurement System product line offers our clients innovative, robust, and accurate solutions to efficiently handle short term compliance measurement on industrial sites.

Control and automation of industrial processes such as combustion, flue gas filtration (cyclone, electrostatic precipitator, deNOx, Scrubbers…) or pyrolysis requires online instrumentation with fast response time and the ability to withstand their harsh installation environment. AquaGas products and systems are conceived to operate 24/7 in the heart of industrial settings bringing key functions, and high precision technologies to automate your industrial processes.

Emissions and Process Instrumentation

AquaGas products and systems are used worldwide and suitable for an extended field of applications including:

Large combustion plants: coal or natural gas fired power stations, cement kilns, furnace flue gas, boilers…

Oil & Gas: coal or biomass gasification or pyrolisis, syngas, chemical and refining facilities…

Manufacturing industries: Mining, paper mills, glass works, offgas from the Steel and Iron industries, blast furnaces, converters, direct iron smelting reduction, endo and exo gas generators for heat treating, pharmaceutical plant, gas production…

Waste management: domestic and industrial waste incinerator, solvent incinerators, water treatment plants, laboratories, anaerobic digestion or fermentation processes, landfills…

https://www.aquagas.com.au/wp-content/uploads/2022/12/Proceas-Durag-01.png

1398

2481

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2024-03-26 22:59:162024-04-08 20:29:19New ProCeas AIR ref in NSW

https://www.aquagas.com.au/wp-content/uploads/2022/12/Proceas-Durag-01.png

1398

2481

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2024-03-26 22:59:162024-04-08 20:29:19New ProCeas AIR ref in NSW https://www.aquagas.com.au/wp-content/uploads/2024/02/AquaGasAirqual1.png

295

706

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2024-02-15 17:52:212024-02-15 18:09:09Empower Your Safety with AIRQUAL-1

https://www.aquagas.com.au/wp-content/uploads/2024/02/AquaGasAirqual1.png

295

706

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2024-02-15 17:52:212024-02-15 18:09:09Empower Your Safety with AIRQUAL-1 https://www.aquagas.com.au/wp-content/uploads/2023/08/AquaGas-Peracetic-Acid.png

732

1097

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-08-19 22:57:512023-08-19 23:20:48Peracetic Acid Exposure Monitoring

https://www.aquagas.com.au/wp-content/uploads/2023/08/AquaGas-Peracetic-Acid.png

732

1097

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-08-19 22:57:512023-08-19 23:20:48Peracetic Acid Exposure Monitoring https://www.aquagas.com.au/wp-content/uploads/2023/08/AquaGas-Snowy-Mountains-project-scaled-e1691936503389.jpeg

1036

2560

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-08-13 14:20:212023-11-09 12:32:49Two CEMS for a Power Station in NSW

https://www.aquagas.com.au/wp-content/uploads/2023/08/AquaGas-Snowy-Mountains-project-scaled-e1691936503389.jpeg

1036

2560

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-08-13 14:20:212023-11-09 12:32:49Two CEMS for a Power Station in NSW https://www.aquagas.com.au/wp-content/uploads/2023/08/AquaGas-DadoLab-Post-Blog-scaled.jpeg

1440

2560

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-08-05 17:39:432023-08-19 22:47:01Cutting-edge solutions for stack emission and environmental sampling

https://www.aquagas.com.au/wp-content/uploads/2023/08/AquaGas-DadoLab-Post-Blog-scaled.jpeg

1440

2560

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-08-05 17:39:432023-08-19 22:47:01Cutting-edge solutions for stack emission and environmental sampling https://www.aquagas.com.au/wp-content/uploads/2023/07/AquaGas-Chemical-Vapor-Monitoring.png

839

1258

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-07-29 14:46:042023-08-08 22:29:26Air Monitoring for Workplace Safety

https://www.aquagas.com.au/wp-content/uploads/2023/07/AquaGas-Chemical-Vapor-Monitoring.png

839

1258

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-07-29 14:46:042023-08-08 22:29:26Air Monitoring for Workplace Safety https://www.aquagas.com.au/wp-content/uploads/2023/07/AquaGas-Ellona-Paris-odour-control-crop.png

1143

2782

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-07-23 13:39:062023-08-19 22:47:16Smart sensors enhance odour control at Paris waste-to-energy plant

https://www.aquagas.com.au/wp-content/uploads/2023/07/AquaGas-Ellona-Paris-odour-control-crop.png

1143

2782

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-07-23 13:39:062023-08-19 22:47:16Smart sensors enhance odour control at Paris waste-to-energy plant https://www.aquagas.com.au/wp-content/uploads/2023/07/AquaGas_Tocadero-Toc_product.png

1812

2644

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-07-09 21:06:292023-08-19 22:47:29TOCADERO TOC, more accurate and reliable measurements

https://www.aquagas.com.au/wp-content/uploads/2023/07/AquaGas_Tocadero-Toc_product.png

1812

2644

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-07-09 21:06:292023-08-19 22:47:29TOCADERO TOC, more accurate and reliable measurements https://www.aquagas.com.au/wp-content/uploads/2023/07/AquaGas-Veolia-Post-scaled.jpg

1920

2560

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-07-07 22:36:302023-08-19 21:35:51Supply of SmartCEMS for multiple projects in Australia and overseas

https://www.aquagas.com.au/wp-content/uploads/2023/07/AquaGas-Veolia-Post-scaled.jpg

1920

2560

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-07-07 22:36:302023-08-19 21:35:51Supply of SmartCEMS for multiple projects in Australia and overseas https://www.aquagas.com.au/wp-content/uploads/2023/06/AquaGas-SO3-monitor-post.png

1763

5042

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-06-04 11:57:412023-11-30 21:28:15SO3 Monitoring System

https://www.aquagas.com.au/wp-content/uploads/2023/06/AquaGas-SO3-monitor-post.png

1763

5042

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-06-04 11:57:412023-11-30 21:28:15SO3 Monitoring System https://www.aquagas.com.au/wp-content/uploads/2023/04/Post-Tunnel-Sensors.png

630

1255

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-04-15 16:35:492023-12-12 23:08:55Introducing FIVES Pillard Tunnel Sensors

https://www.aquagas.com.au/wp-content/uploads/2023/04/Post-Tunnel-Sensors.png

630

1255

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-04-15 16:35:492023-12-12 23:08:55Introducing FIVES Pillard Tunnel Sensors https://www.aquagas.com.au/wp-content/uploads/2023/04/Post-CEMS.png

303

726

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-04-12 22:28:342023-11-15 23:58:11Continuous Emissions Monitoring Systems

https://www.aquagas.com.au/wp-content/uploads/2023/04/Post-CEMS.png

303

726

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-04-12 22:28:342023-11-15 23:58:11Continuous Emissions Monitoring Systems https://www.aquagas.com.au/wp-content/uploads/2023/04/Aquagas-Blog-Sustainable-Packaging.png

1679

2510

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-04-12 22:26:302023-10-12 20:04:10Mobile CEMS for sustainable packaging

https://www.aquagas.com.au/wp-content/uploads/2023/04/Aquagas-Blog-Sustainable-Packaging.png

1679

2510

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-04-12 22:26:302023-10-12 20:04:10Mobile CEMS for sustainable packaging https://www.aquagas.com.au/wp-content/uploads/2023/04/Aquagas-Multi-Metal-Smelter3.png

630

1255

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-04-12 22:16:162023-05-19 09:12:23Multi-metal smelter partners with AquaGas

https://www.aquagas.com.au/wp-content/uploads/2023/04/Aquagas-Multi-Metal-Smelter3.png

630

1255

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-04-12 22:16:162023-05-19 09:12:23Multi-metal smelter partners with AquaGas https://www.aquagas.com.au/wp-content/uploads/2023/04/Aquagas-Blog-Fertilising-Plant.png

684

2510

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-04-12 21:53:552023-10-12 20:44:24AquaGas SmartCEMS at the largest fertilisers plant

https://www.aquagas.com.au/wp-content/uploads/2023/04/Aquagas-Blog-Fertilising-Plant.png

684

2510

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-04-12 21:53:552023-10-12 20:44:24AquaGas SmartCEMS at the largest fertilisers plant https://www.aquagas.com.au/wp-content/uploads/2023/04/Aquagas-Ellona-Copper-facility.jpg

953

1429

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-04-03 22:54:122023-08-19 20:31:26NH3 AQMS in South Australia

https://www.aquagas.com.au/wp-content/uploads/2023/04/Aquagas-Ellona-Copper-facility.jpg

953

1429

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-04-03 22:54:122023-08-19 20:31:26NH3 AQMS in South Australia https://www.aquagas.com.au/wp-content/uploads/2023/04/Aquagas-Ellona-Copper-mine.jpg

882

1920

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-04-03 22:39:112023-07-29 13:00:138 AQMS for a Copper Mine

https://www.aquagas.com.au/wp-content/uploads/2023/04/Aquagas-Ellona-Copper-mine.jpg

882

1920

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-04-03 22:39:112023-07-29 13:00:138 AQMS for a Copper Mine https://www.aquagas.com.au/wp-content/uploads/2022/10/Screenshot-2022-10-03-at-23.35.03.png

769

1152

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-04-03 22:23:002023-07-29 12:53:59IAQ Sensors for Chemical Facilities in QLD

https://www.aquagas.com.au/wp-content/uploads/2022/10/Screenshot-2022-10-03-at-23.35.03.png

769

1152

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-04-03 22:23:002023-07-29 12:53:59IAQ Sensors for Chemical Facilities in QLD https://www.aquagas.com.au/wp-content/uploads/2023/04/Aquagas-Ellona-Offices-and-Warehouses-across-Australia-scaled.jpg

1440

2560

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-04-03 22:13:532023-07-29 12:46:19Indoor air quality in offices and warehouses

https://www.aquagas.com.au/wp-content/uploads/2023/04/Aquagas-Ellona-Offices-and-Warehouses-across-Australia-scaled.jpg

1440

2560

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-04-03 22:13:532023-07-29 12:46:19Indoor air quality in offices and warehouses https://www.aquagas.com.au/wp-content/uploads/2023/04/Aquagas-Ellona-Distributor.png

1340

2001

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-04-03 21:52:192023-07-29 12:26:11Ellona Distributor for Australia

https://www.aquagas.com.au/wp-content/uploads/2023/04/Aquagas-Ellona-Distributor.png

1340

2001

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-04-03 21:52:192023-07-29 12:26:11Ellona Distributor for Australia https://www.aquagas.com.au/wp-content/uploads/2022/12/GHG_contract.png

1080

1920

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2022-12-18 19:31:092022-12-22 19:39:17Greenhouse Gases (GHG) Fugitive Emissions

https://www.aquagas.com.au/wp-content/uploads/2022/12/GHG_contract.png

1080

1920

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2022-12-18 19:31:092022-12-22 19:39:17Greenhouse Gases (GHG) Fugitive Emissions https://www.aquagas.com.au/wp-content/uploads/2022/12/GH2_contract.png

1080

1920

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2022-12-18 19:16:332023-03-13 22:23:16SmartCEMS® GH2 deployed @ multiple GH2 facilities across Australia

https://www.aquagas.com.au/wp-content/uploads/2022/12/GH2_contract.png

1080

1920

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2022-12-18 19:16:332023-03-13 22:23:16SmartCEMS® GH2 deployed @ multiple GH2 facilities across Australia https://www.aquagas.com.au/wp-content/uploads/2022/12/UQ-1038x555-1.png

555

1038

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2022-12-16 00:18:192022-12-22 19:57:00SmartCEMS® GHG

https://www.aquagas.com.au/wp-content/uploads/2022/12/UQ-1038x555-1.png

555

1038

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2022-12-16 00:18:192022-12-22 19:57:00SmartCEMS® GHG https://www.aquagas.com.au/wp-content/uploads/2022/12/Aquagas-Thank-You.png

1080

1920

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2022-12-15 23:34:242022-12-21 13:54:07A note of thanks

https://www.aquagas.com.au/wp-content/uploads/2022/12/Aquagas-Thank-You.png

1080

1920

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2022-12-15 23:34:242022-12-21 13:54:07A note of thanks https://www.aquagas.com.au/wp-content/uploads/2022/12/Aquagas-Happy-New-Year.png

1081

1921

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2022-12-15 22:34:272023-01-01 19:31:58Warmth, joy, and peace from our crew to yours!

https://www.aquagas.com.au/wp-content/uploads/2022/12/Aquagas-Happy-New-Year.png

1081

1921

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2022-12-15 22:34:272023-01-01 19:31:58Warmth, joy, and peace from our crew to yours! https://www.aquagas.com.au/wp-content/uploads/2022/11/GH2-Cycle-3_website.png

1763

4168

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2022-11-16 00:24:382022-12-21 13:54:53PROCEAS® in GH2 Plants

https://www.aquagas.com.au/wp-content/uploads/2022/11/GH2-Cycle-3_website.png

1763

4168

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2022-11-16 00:24:382022-12-21 13:54:53PROCEAS® in GH2 Plants https://www.aquagas.com.au/wp-content/uploads/2022/11/Banner-AquaGas-4-scaled.jpg

931

2560

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2022-11-15 00:02:252022-12-22 19:55:11SmartCEMS® in GH2 Plants

https://www.aquagas.com.au/wp-content/uploads/2022/11/Banner-AquaGas-4-scaled.jpg

931

2560

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2022-11-15 00:02:252022-12-22 19:55:11SmartCEMS® in GH2 Plants https://www.aquagas.com.au/wp-content/uploads/2022/11/GH2-Cycle-3_website.png

1763

4168

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2022-11-14 23:03:572022-12-21 13:55:52GREEN HYDROGEN [GH2]

https://www.aquagas.com.au/wp-content/uploads/2022/11/GH2-Cycle-3_website.png

1763

4168

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2022-11-14 23:03:572022-12-21 13:55:52GREEN HYDROGEN [GH2]

https://www.aquagas.com.au/wp-content/uploads/2016/05/MAMOS-Multigas-analyser-CEMS.jpg

2247

2295

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2018-11-03 07:11:482022-12-20 11:48:03AquaGas SmartCEMS® solution

https://www.aquagas.com.au/wp-content/uploads/2016/05/MAMOS-Multigas-analyser-CEMS.jpg

2247

2295

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2018-11-03 07:11:482022-12-20 11:48:03AquaGas SmartCEMS® solution https://www.aquagas.com.au/wp-content/uploads/2018/04/Woehler_A-550_Industrial_INT-1.jpg

1334

1999

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2018-09-13 05:24:162022-12-15 22:26:41A 550 Industrial Handheld Analyser

https://www.aquagas.com.au/wp-content/uploads/2018/04/Woehler_A-550_Industrial_INT-1.jpg

1334

1999

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2018-09-13 05:24:162022-12-15 22:26:41A 550 Industrial Handheld Analyser https://www.aquagas.com.au/wp-content/uploads/2018/09/Stack-testing-AquaGas-Pty-Ltd.jpg

1035

2552

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2018-09-13 03:46:422022-10-05 22:19:06NOx Emissions Testing

https://www.aquagas.com.au/wp-content/uploads/2018/09/Stack-testing-AquaGas-Pty-Ltd.jpg

1035

2552

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2018-09-13 03:46:422022-10-05 22:19:06NOx Emissions Testing https://www.aquagas.com.au/wp-content/uploads/2018/09/Banner_Airqual.png

524

1500

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2018-09-13 03:13:282024-01-19 00:50:08Breathing Air Quality

https://www.aquagas.com.au/wp-content/uploads/2018/09/Banner_Airqual.png

524

1500

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2018-09-13 03:13:282024-01-19 00:50:08Breathing Air Quality https://www.aquagas.com.au/wp-content/uploads/2018/09/OPENPITATNIGHT.png

713

1600

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2018-09-13 02:23:232022-10-05 22:17:42Flammable and toxic Offgas

https://www.aquagas.com.au/wp-content/uploads/2018/09/OPENPITATNIGHT.png

713

1600

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2018-09-13 02:23:232022-10-05 22:17:42Flammable and toxic Offgas https://www.aquagas.com.au/wp-content/uploads/2018/08/GOLD-COAST-AUSTRALIA.jpg

736

1494

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2018-08-02 05:38:082022-10-05 22:52:20City Of Gold Coast

https://www.aquagas.com.au/wp-content/uploads/2018/08/GOLD-COAST-AUSTRALIA.jpg

736

1494

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2018-08-02 05:38:082022-10-05 22:52:20City Of Gold Coast https://www.aquagas.com.au/wp-content/uploads/2018/08/Clean-Air-AquaGas.jpg

1000

1920

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2018-08-02 04:57:012022-10-05 22:25:23Odour Control Systems

https://www.aquagas.com.au/wp-content/uploads/2018/08/Clean-Air-AquaGas.jpg

1000

1920

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2018-08-02 04:57:012022-10-05 22:25:23Odour Control Systems

https://www.aquagas.com.au/wp-content/uploads/2022/09/E3_site.png

524

1500

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2018-07-30 03:03:372022-12-15 22:30:20WT1 Fence Line Monitoring Solution

https://www.aquagas.com.au/wp-content/uploads/2022/09/E3_site.png

524

1500

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2018-07-30 03:03:372022-12-15 22:30:20WT1 Fence Line Monitoring Solution

https://www.aquagas.com.au/wp-content/uploads/2015/03/slide1.jpg

314

1300

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2017-04-12 03:45:312022-10-10 22:22:39More on AquaGas.com.au

https://www.aquagas.com.au/wp-content/uploads/2015/03/slide1.jpg

314

1300

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2017-04-12 03:45:312022-10-10 22:22:39More on AquaGas.com.au https://www.aquagas.com.au/wp-content/uploads/2017/04/sydney-AquaFID-CEMS.jpg

400

1200

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2017-04-12 03:25:292022-10-10 22:28:36AquaFID THC CEMS – Continuous Emissions Monitoring Systems

https://www.aquagas.com.au/wp-content/uploads/2017/04/sydney-AquaFID-CEMS.jpg

400

1200

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2017-04-12 03:25:292022-10-10 22:28:36AquaFID THC CEMS – Continuous Emissions Monitoring Systems

https://www.aquagas.com.au/wp-content/uploads/2016/05/1217512_shortfin-barracuda-le-nouveau-sous-marin-phare-de-dcns-web-tete-021878385540.jpg

533

1000

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2016-05-15 00:41:552023-03-06 22:16:26Indoor air quality

https://www.aquagas.com.au/wp-content/uploads/2016/05/1217512_shortfin-barracuda-le-nouveau-sous-marin-phare-de-dcns-web-tete-021878385540.jpg

533

1000

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2016-05-15 00:41:552023-03-06 22:16:26Indoor air quality

https://www.aquagas.com.au/wp-content/uploads/2015/12/Nickelhub__014_-scaled.jpg

1707

2560

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2016-01-14 11:04:022023-03-06 23:07:02Process monitoring in biogas plants

https://www.aquagas.com.au/wp-content/uploads/2015/12/Nickelhub__014_-scaled.jpg

1707

2560

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2016-01-14 11:04:022023-03-06 23:07:02Process monitoring in biogas plants https://www.aquagas.com.au/wp-content/uploads/2015/10/chemical_carousel.jpg

486

1296

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2015-10-20 10:22:412023-03-13 22:50:46Online analysis in the Chlorine industry

https://www.aquagas.com.au/wp-content/uploads/2015/10/chemical_carousel.jpg

486

1296

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2015-10-20 10:22:412023-03-13 22:50:46Online analysis in the Chlorine industry

Emissions and Process Instrumentation

Emissions and Process Instrumentation

SO2, NO, NO2, N2O, CO, HCl, NH3, CH4, CO2, H2O, O2, CS2, H2, VOCs, THC, NMHC, TRS, H2S, SO3 (for others please contact us)

POPs – Persistent Organic Pollutants

POPs have been determined to be the most significant part of emissions to the environment which cause adverse health effects. These include, dioxins (PCCD/F), polychlorinated biphenyls (PCBs), polyaromatic hydrocarbons (PAHs), Hexachlorobenzene (HCB) and others. These compounds have a high stability, low volatility, and are degraded very slowly. Due to their lipophilic character, an accumulation in the human body takes place.

Fine dust

TSP, PM10, PM2.5, PM1 are the portions of solids in gases being the focus of concern for pulmonary health effects.

Combustion Gases

O2 and combustibles online monitoring for the control of combustion processes in large scale industrial facilities.

Comprehensive range of stack emissions monitoring equipment for continuous emissions monitoring of dust, opacity, flow and gases including Mercury.

Large range of portable analysers for short to medium term stack testing and process monitoring.

Emissions and Process Instrumentation

Emissions and Process Instrumentation

Sampling is the key factor to ensure reliable representative analysis and is essential to preserve the good status of your monitoring system. AquaGas supplies stationary sampling equipment designed for Continuous Emission Monitoring and Process Control Systems as well as Portable Emissions Measurement System for short term monitoring. Our solutions are available as system components for integration into an existing CEMS or as a complete turnkey Automatic Monitoring Systems. AquaGas integrated solutions combine the best technologies available to extract, transfer, and condition samples from stack or process gasses prior to analysis. Our adaptive product range is versatile and suits a large field of applications and requirements

Emissions and Process Instrumentation