Applications

in the Oil and Gas industry.

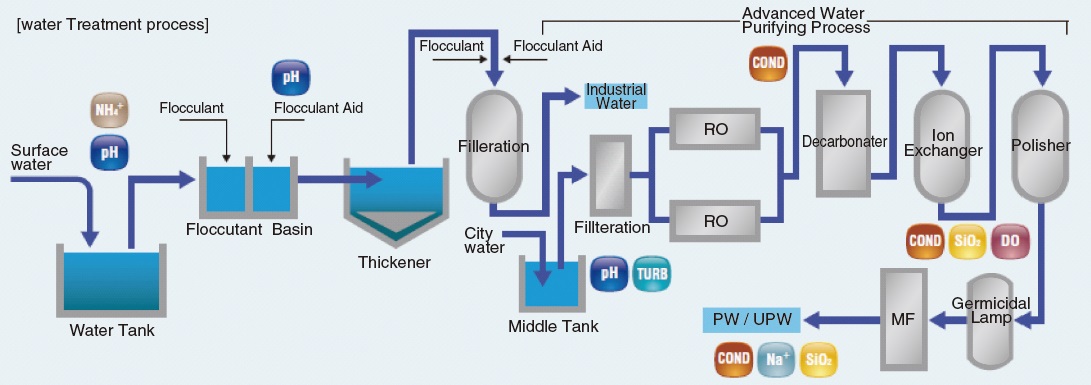

Water treatment plant in refineries and other oil and gas processes requires the use of tank for storage purposes and as part of the wastewater management plan. The composition of the air confined in the tank headspace provides a good indication of the level of contamination in the wastewater influents. Monitoring gas in tank headspaces also becomes mandatory when it comes to managing oils contaminated water. Explosion risks but also the corrosion and degradation factor are controlled with the blanketing whose automation can largely be optimised by the online measurement of gas concentrations in the headspace. Moreover there is a large number of compounds that will adduce plant operators detailed information with regards to filtration and decantation processes.

Tank Blanketing Automation

Tank blanketing is the process of filling the headspace in storage vessels and reactors with an inert gas, usually to protect its contents from exploding, degrade but also to protect equipment from corrosion. As oxygen and moisture in the air can be undesired in numerous processes and applications, blanketing is done in a wide range of industries, varying from petrochemicals to food and beverage, pharmaceutical to pure water. Inerting is done for similar reasons but is not limited to storage tanks and reactors only. Any confined space can be sparged with an inert gas to create the desired atmosphere. This ranges from packing food under protective atmosphere to increase shelf life to lowering the oxygen concentration in rooms where welding takes place to reduce risk of fire.

Wrongly engineered or poorly maintained blanketing systems may lead to serious incidents, degraded plant operations and pollution events. A malfunctioning may cause the tank to implode or causes the leaking of air into the tank, which, as mentioned, can have consequences with regard to product quality and, depending on the stored product, can seriously increase risk of explosion.

One way to increase safety and reduce the use of blanketing gas (nitrogen, air…) simultaneously is to control inertisation as a function of gas concentration in the headspace. Depending on the product and the reason for blanketing and inerting, there are tolerances when it comes down to the maximum allowable oxygen, VOCs or other combustibles concentration. Certain monomers require zero percent oxygen to prevent polymerization. Others require a small amount of oxygen for the same reason. In the case of explosion protection, the oxygen concentration does not necessarily need to be zero. In fact for all solvents a so called limiting oxygen concentration exists. Below this concentration there is no risk of explosion. It is obvious that controlling the tank headspace purge based on the concentration will seriously cut nitrogen or other blanketing gas costs. Furthermore the measurement of gas concentrations in the tank headspace provides an important safety parameter. Thresholds such as Limiting Oxygen Concentration (LOC), Maximum Oxygen Concentration (MOC), Lower Explosive Limit (LEL) indicate application and gas specific limits in terms of concentration.

For example, two threshold values are established for the oxygen concentration in the tank headspace, well below the Limiting Oxygen Concentration; the Lower Intervention Level and the Upper Intervention Level. These two threshold values are the set-points that control the purging sequences. The moment the oxygen concentration reaches the Lower Intervention Limit, the nitrogen flow is intermittent. Purging of the vessel is resumed when the upper intervention limit is exceeded. This means that the inerting system keeps the consumption of nitrogen minimal while safe operation is ensured.

Depending on individual process conditions and solvent; O2, H2O and LEL are usually the main parameters of interest. However when odour control is implemented NH3, H2S and VOCs can be added to the monitored parameters.

To meet the needs of the waste recycling facilities, AquaGas offers a unique fully automatic solution for realtime measurement of gas concentrations in Tank Headspaces. AquaGas THMS features the association of a MAMOS multigas analyser fitted with a combination of 9 gas proprietary measuring cells with a field proven, robust and dedicated Exproof sampling train. The system can be multiplexed for controlling up to 4 tank headspaces. Both the gas sampling probe located at the top of the tank and the sample line are temperature controlled above the gas dew point. Depending on the application, the gas can also be fitted with the optional backflush, temperature sensor, insitu filter… The onboard PLC offers a large panel of IOs as required to handle blanketing regulator, breathing valve, safety relief valve…

The THMS is integrated in Australia by AquaGas for continuous and simultaneous measurement of VOC, NH3, CO, CO2, LEL, CxHy, H2S and O2 inside tank headspaces.

Advantages of AquaGas THMS

The AquaGas THMS is a cost efficient and safe solution available in a compact wall mount IP56 enclosure that totally eliminates the need for multiple sensors and probes. The sampling probe can be mounted directly into the vessel or blanketing gas discharge piping and is rated for high dust, moisture or solvents loads. A retractable filter assembly allows cleaning of the sampling probe without the need for dismounting the probe from its matching flange. Zero calibration is performed automatically on a daily basis while span gas calibration is only required quarterly. In very critical applications, the system can be equipped with redundant probes and or sensors for additional safety and self check purposes. Compared to traditional analyser technology, the AquaGas THMS is available at only a fraction of the costs. The most valued perceived benefit however is the significant increase of safety, enormous savings on tank maintenance as well as the optimised process operations.

Integrated Systems and Customised Services

For better environmental performances.

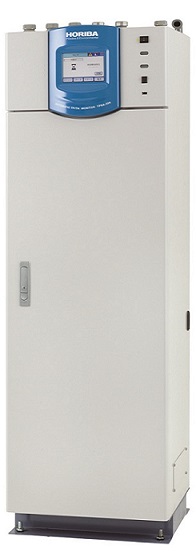

Ammonium, Free or Total Chlorine, Hydrazine, Morphine, Phenol, Sulfates, Colour, Silica, Phosphates (Orthophosphates), Hardness, Aluminium, Chromium VI, Iron, Nickel, Lead, Zinc, TH, Alkalinity, Chlorides, Cyanides, Fluorides, Peracetic acid VFA, CaM…

SERES® online water quality analyser offers multiple sensor and method configurations. Here are the typical measuring parameter calibrated on the TOPAZ unit. For other parameters or different measuring ranges (MR), please consult us.

NO, NO2, NOx, SO2, CO, HCl, CO2, H2O, H2S, NH3, N2O, COS, SO3, CH4, HF, HCN, H2…

Our strong partnerships implemented with world leading CEMS and Process gas analyser manufacturers as well as local distributors, provide AquaGas with an extensive range of technologies, diverse measuring principle and sampling methods to design and build cost effective, versatile and high performance systems composed of instruments specifically selected in consideration of the applications.

Data Aquisition Software (CDAS) is a fully MCERTS accredited (parts A, B, C1 & C2) real time data acquisition software – now available for touch screens and windows 10. CDAS is customisable and flexible, allowing it to collect raw data from a range of instruments for CEMS

Isokinetic sampler developed for short to medium term emissions monitoring, fulfilling all the requirements of the dioxins and persistent organic compounds (POPs), PCBs, metals, HCB and fine dust measurement standard within the same sampling train

O2, CO, CO2, NO, NO2, SO2, H2S, H2, CL2, N2O and VOCs

Professional flue gas analyser combining high quality of sample conditioning with great measurement accuracy for continuous emissions monitoring or online process measurement of up to 9 gases simultaneously.